Why Ignoring a Small Screw Hole is a Big Mistake

When you need to patch screw holes in metal roof panels, you’re looking at a straightforward repair that takes 1-2 hours and costs $15-$50 for materials. Prefer a pro? Get help from our professional roofing services at Apex Roofing & General Contractors. Here’s the quick answer:

Essential Steps to Patch Screw Holes:

- Clean the area with a wire brush and degreaser

- Apply roofing sealant (polyurethane or butyl) directly into the hole

- Insert an oversized screw with a neoprene washer for larger holes

- Seal over the screw head with additional sealant

- Allow 24-48 hours to cure before exposing to moisture

That tiny hole in your metal roof might look harmless, but it’s a direct pipeline for water damage. A single unpatched screw hole can allow water to infiltrate your home, leading to mold, rot, and structural issues that cost thousands to repair. The good news? This is a manageable DIY repair. Proactive maintenance and timely roof repair are the best ways to ensure your roof lasts a lifetime. Water infiltration through unsealed holes can lead to mold, mildew, and insulation damage—problems that escalate quickly if left unaddressed.

Metal roofs can last 50 years or more, but only with proper maintenance. A correctly installed patch can last 10-15 years. The alternative is ignoring these entry points, which leads to spreading rust, compromised roof decking, ceiling stains, and costly structural repairs or premature roof replacement.

I’m Carlos Yzaguirre, President of Apex Roofing & General Contractors, and I’ve seen how proactive homeowners who patch screw holes early avoid expensive emergency repairs. My team has helped hundreds of San Antonio property owners protect their investments through proper maintenance.

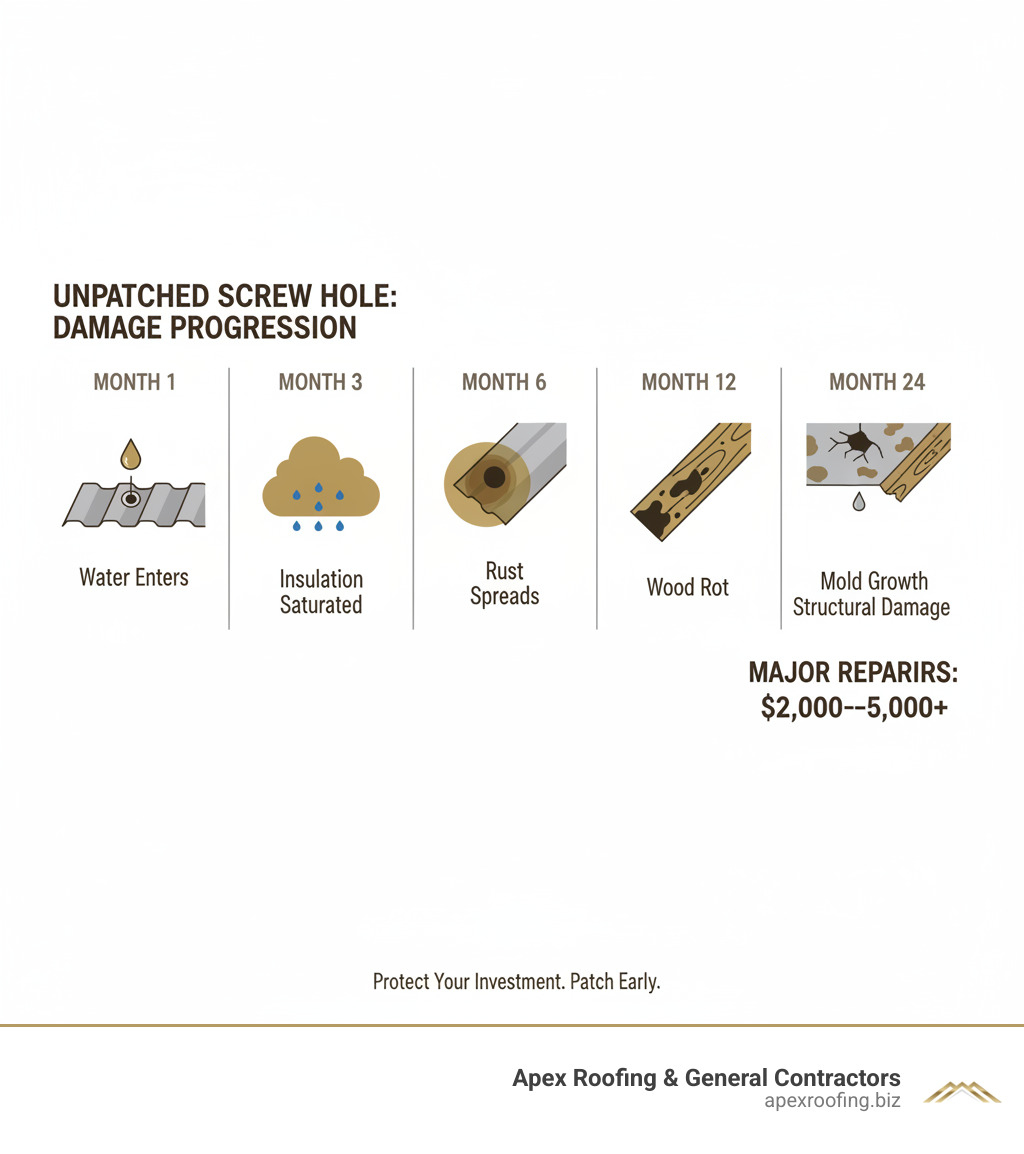

This infographic illustrates how a single 1/4-inch screw hole progresses over 12-24 months: Month 1—water enters hole; Month 3—insulation becomes saturated; Month 6—rust forms around hole and spreads; Month 9—wood decking shows rot; Month 12—mold growth visible on interior ceiling; Month 18—structural wood support weakens; Month 24—ceiling damage and potential safety hazard requiring $2,000-$5,000 in repairs.

Signs of a Leak

The most obvious sign of a leak from a screw hole is a water stain on your ceiling or walls. However, other signs can appear even before a stain becomes visible. Be vigilant for these indicators:

- Water Stains: Yellow, brown, or black discoloration on interior ceilings or walls, often directly beneath the compromised area. Their size can indicate the severity of the leak.

- Mold and Mildew: A musty odor or visible fuzzy growths on ceilings, walls, or in the attic are strong indicators of water infiltration. The Environmental Protection Agency (EPA) provides a comprehensive guide on mold and moisture, highlighting its dangers.

- Damaged Insulation: Water quickly saturates attic insulation, causing it to become matted, heavy, and ineffective. This leads to higher energy bills.

- Rust and Corrosion: Constant moisture from unsealed holes will cause rust, which weakens the metal panels and can spread, creating larger problems.

- Structural Weakening: The most severe consequence is water rotting the wooden decking, rafters, and other structural components, compromising your roof’s integrity and safety.

Before You Begin: Safety, Tools, and Materials

Before you climb onto that roof to patch screw holes in metal roof panels, a serious conversation about safety is in order. At Apex Roofing & General Contractors, we prioritize safety on every job in San Antonio, and you should too. Working at heights is inherently dangerous, and proper preparation is non-negotiable.

Most roofing accidents are preventable. Whether you’re a seasoned DIYer or tackling your first roofing repair project, following safety protocols is the difference between a successful repair and a trip to the emergency room.

Safety First

Always check the weather forecast. Work on a clear, dry day with minimal wind. Metal roofs are extremely slippery when wet, and even morning dew can create a hazardous situation. Never attempt repairs during winter or rainy conditions. Moisture prevents sealants from adhering properly, as most require temperatures above 40-50°F to cure. For an active leak in bad weather, use a temporary tarp and wait for ideal conditions for a permanent fix.

Ladder Safety

Position your ladder on firm, level ground, extending it at least three feet above the roof edge for a secure handhold. Set the ladder at a 4:1 angle—one foot away from the wall for every four feet of height. Always maintain three points of contact (two hands and one foot, or two feet and one hand) when climbing.

Personal Protective Equipment (PPE)

Your safety gear is essential. Non-slip boots provide critical traction on metal surfaces. Heavy-duty gloves protect your hands from sharp edges and chemicals, while safety goggles shield your eyes from debris and sealant splashes. For steep roofs, a safety harness secured to a proper anchor point is mandatory. We follow the essential safety guidelines for roofing workers from OSHA, and you should too.

Essential Tools for the Job

Gathering your tools beforehand makes the job faster and safer. You will need:

- Wire brush

- Caulking gun

- Putty knife

- Cordless drill

- Metal snips (for larger patches)

- Clean cloths or rags

- Measuring tape and marker

Choosing the Right Patching Materials

The material you choose must be compatible with your existing roof to prevent galvanic corrosion—an electrochemical reaction between dissimilar metals that can create bigger problems. Matching materials is critical.

| Sealant Type | Best Use Case | Longevity | Notes |

|---|---|---|---|

| Polyurethane Sealant | Versatile, strong adhesion, flexible | 10-20 years | Excellent for general metal roof repairs, good UV resistance. |

| Silicone Sealant | Excellent elasticity, good UV resistance | 10-20 years | Can be harder to paint over, but great for sealing. |

| Butyl Sealant | Aggressive adhesion, good for seams and fasteners | 10-15 years | Often used in tapes, good for initial adhesion. |

For the repair, you’ll need a high-quality urethane sealant for its flexibility and adhesion. For larger holes, use metal patch material that matches your roof’s metal type. Oversized roofing screws (e.g., #14 Type 17 Woodbinder) are designed to fill existing holes effectively. Neoprene washers create a watertight seal under the screw head. Finally, have all-purpose cleaner and mineral spirits or acetone on hand for cleaning and degreasing the repair area to ensure a strong sealant bond.

How to Patch Screw Holes in a Metal Roof: A Step-by-Step Guide

With your tools and materials ready, it’s time to get to work. When you patch screw holes in a metal roof, you are creating a durable, watertight seal that restores your roof’s integrity. These steps will guide you through a professional-quality repair for any small opening.

Step 1: Preparing the Area to Patch Screw Holes in a Metal Roof

Surface preparation is the most critical step for a lasting repair. A clean, properly prepared surface is absolutely essential for sealant adhesion. A thorough metal roof patch always begins with meticulous cleaning.

First, use a stiff brush and all-purpose cleaner to remove all dirt, debris, and algae in a 6-inch radius around the hole. Next, use a wire brush or sandpaper to scrub away any rust. For galvanized metal, lightly scuff the immediate repair area to create a rough texture that improves adhesion. Finally, wipe the area with mineral spirits or acetone to degrease it, then ensure it is completely dry before proceeding. Any moisture will compromise the sealant’s bond.

Step 2: Applying Sealant and the Patch

This step varies based on the size of the hole.

For a small hole repair, such as a missing screw, apply a generous amount of high-quality urethane or silicone sealant directly into and over the hole. For a more robust seal, insert an oversized roofing screw with a neoprene washer. Drive the screw until the washer bulges slightly, creating a tight seal. Do not overtighten, as this can dimple the metal and create a new spot for water to collect.

For a large hole repair, where the metal is damaged, you’ll need a patch. Cut a piece of matching metal that extends at least 2 inches beyond the hole on all sides. Round the corners to prevent them from catching. Apply a bead of sealant around the hole on the roof, and also apply sealant to the underside of the patch. Center the patch over the hole and press firmly, allowing sealant to squeeze out from the edges. Secure the patch with oversized screws and neoprene washers every 2-3 inches around the perimeter. Drive them just tight enough to secure the patch to the panel, not into the decking below.

Step 3: Sealing and Finishing the Repair

This final step ensures a completely waterproof, professional-quality fix.

Apply another bead of sealant around the entire perimeter of the patch and over all screw heads. Use a putty knife or gloved finger to smooth or “tool” the sealant, creating a clean, seamless barrier. Remove any excess sealant with a rag before it cures.

Allow the sealant to fully cure according to the manufacturer’s instructions, which typically takes 24 to 48 hours. Rushing this step is a common mistake that can cause the repair to fail. Once cured, perform a water test by gently spraying the area with a hose and checking for leaks from underneath. If you see moisture, apply more sealant and retest after it cures.

For aesthetic purposes, you can paint the patched area to match your roof color once the sealant is fully cured. Ensure the paint is compatible with the sealant material.

After the Repair: Maintenance and When to Call a Professional

A successful patch isn’t the final step. Ongoing maintenance and knowing when a job is too big are key to your roof’s longevity. Proactive care saves money and keeps your home safe and dry for decades.

Best Practices to Patch Screw Holes in a Metal Roof for Longevity

A properly installed patch can last 10-15 years with regular care. Stay ahead of problems with these best practices:

- Bi-annual Inspections: Check your roof each spring and fall. Look for loose fasteners, deteriorating sealant, new damage, or spreading rust.

- Re-apply Sealant: Sealants degrade over time from UV exposure and temperature changes. If you see cracked or peeling sealant, clean the area and apply a fresh layer.

- Address Rust Immediately: Clean small rust spots with a wire brush, apply a rust-inhibiting primer, and seal or paint the area. Catching rust early prevents it from spreading.

- Trim Overhanging Branches: Keep tree branches at least six feet from your roofline to prevent them from scratching coatings or loosening screws.

- Document Repairs: Keep a log of repair dates and locations to track problem areas and identify recurring issues that may need professional attention.

When DIY Isn’t Enough: Calling a Roofing Expert

While patching small holes is a manageable DIY task, significant damage requires professional expertise. Attempting large-scale repairs without the right skills or equipment can turn a minor issue into a major expense.

Call a professional for:

- Extensive Damage: Numerous holes, large tears, or buckled panels require a comprehensive assessment. A single professional patch may cost $150-$600, but widespread issues need a strategic plan.

- Multiple Leaks: Leaks scattered across the roof suggest a systemic problem, like improper installation or aging materials, that needs professional diagnosis.

- Signs of Structural Sagging: A dipping roofline or sagging interior ceilings indicate water has damaged the support structure. This is a safety hazard requiring immediate professional intervention.

- Widespread Corrosion: Corrosion across multiple panels means the roof’s protective coating has failed and the system’s integrity is compromised.

- Access or Safety Concerns: If you are uncomfortable with heights, lack proper safety equipment, or have a steep roof, prioritize your safety and call a professional.

- Warranty Concerns: Many manufacturer warranties are voided by DIY repairs. Always check your warranty documents first; repairs may need to be done by a certified contractor.

If you’re in the San Antonio area and facing complex issues, our roofers near you in San Antonio can provide a professional assessment. We have the experience to handle all types of metal roof repairs. Contact us at (726) 727-7663 for an honest assessment.

Frequently Asked Questions about Patching Metal Roofs

Will patching screw holes affect my roof’s warranty?

Yes, DIY repairs can void your manufacturer’s warranty. Most metal roof manufacturers require that all repairs be performed by authorized or certified contractors to keep the warranty valid. This ensures repairs are done correctly and the roof continues to perform as designed. Before starting any work, review your warranty documents. If you’re unsure, call us at (726) 727-7663—we can review your warranty and recommend the best path forward.

Can I repair my metal roof in rainy or cold weather?

No, you should not attempt to patch a metal roof in rainy or cold weather. Most roofing sealants require dry surfaces and temperatures above 40-50°F to cure properly. Cold temperatures make sealants stiff and difficult to apply, preventing a strong bond. Rain is even more problematic, as moisture prevents adhesion and can get trapped under the patch, causing immediate failure. For urgent leaks in bad weather, a temporary fix can be applied, but a permanent repair must wait for clear, dry conditions.

What are the long-term consequences of not patching screw holes?

Unpatched screw holes will inevitably lead to water infiltration, one of the most destructive forces your home can face. The consequences are severe and costly:

- Saturated Insulation: Water ruins attic insulation, causing higher energy bills as your HVAC system works harder.

- Mold and Mildew: Persistent moisture creates a perfect environment for mold growth, which can be harmful to your home’s structure and your family’s health, as detailed in the EPA’s guide to mold and moisture.

- Structural Rot: Water rots the wooden decking, rafters, and joists, weakening your roof’s structural integrity and creating safety hazards.

According to the National Association of Home Builders’ study on the life expectancy of home components, proper maintenance is key. A metal roof should last over 50 years, but neglecting to patch screw holes in a metal roof can cut that lifespan in half.

Protect Your Investment with Professional Care

Patching a few screw holes is a smart DIY task that prevents major headaches. However, sometimes a simple fix can reveal bigger issues. If you’re facing widespread damage, multiple problem areas, or you’re simply not confident about tackling the repair yourself, professional help is the safest and most effective option.

The team at Apex Roofing & General Contractors has the expertise to handle any metal roof repair, from small patches to complete panel replacements. We’ve seen it all in our years serving the San Antonio area, and we know what it takes to ensure your home is protected. When you work with certified professionals, you get peace of mind, warrantied work, and the confidence that your roof was fixed right the first time.

We’re proud to serve homeowners throughout San Antonio, Helotes, Leon Valley, Alamo Heights, Fair Oaks Ranch, Shavano Park, Terrell Hills, and all of Bexar County. Our certified team brings transparent communication and reliable service to every project. Whether you need to patch screw holes in a metal roof or address more extensive damage, we provide comprehensive assessments and honest recommendations.

Don’t let small problems turn into expensive emergencies. If you’re uncertain about the extent of your roof damage or want a professional evaluation, we’re here to help. We offer free estimates—call us at (726) 727-7663 for a free inspection. Your roof is one of your home’s most important investments—let’s make sure it’s protected properly.