Why Your Metal Roof Deserves a Proper Patch

A metal roof patch is a targeted repair solution that stops leaks, prevents water damage, and extends the life of your roof—often at a fraction of the cost of a full replacement. It’s a critical part of the expert roofing services that keep your home protected. Here’s what you need to know:

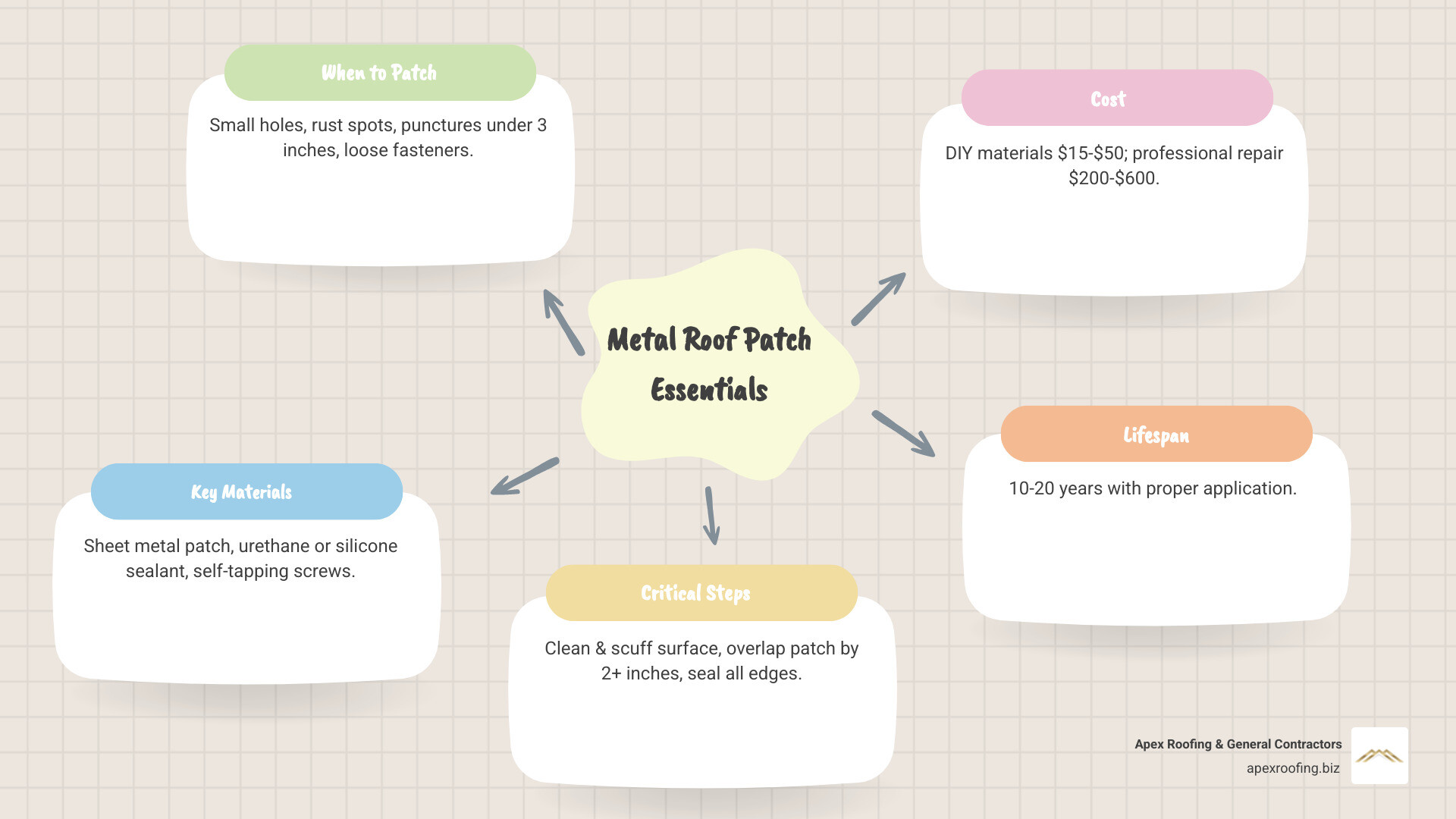

Quick Answer: Metal Roof Patch Essentials

- When to patch: Small holes, rust spots, punctures under 3 inches, loose fasteners

- Key materials: Sheet metal patch, urethane or silicone sealant, self-tapping screws

- Critical steps: Clean and scuff the surface, overlap patch by 2+ inches, seal all edges

- Cost: DIY materials $15-$50; professional repair $200-$600

- Lifespan: 10-20 years with proper application

Metal roofs are renowned for their durability, often lasting 40 to 70 years with proper maintenance. But even the toughest metal can suffer damage from hail storms, falling branches, or simple wear and tear. According to industry data, patching a hole in a metal roof costs an average of $375, while ignoring the problem can lead to water damage, mold growth, and structural issues that cost thousands to repair.

The challenge with metal roof patches isn’t just slapping on some sealant and calling it done. Metal expands and contracts with temperature swings—a reality our roofers in San Antonio manage every season—which means your patch needs to move with the roof or it will fail. Research shows that the most common problem with metal roof patches is inadequate surface preparation and improper sealing, which leads to premature failure and recurring leaks.

Whether you’re a homeowner who spotted a leak during the last storm or a property manager dealing with an aging roof, understanding the proper patching technique can save you significant money and headaches. For more complex issues or widespread damage, professional roof repair services ensure a lasting solution.

I’m Carlos Yzaguirre, President of Apex Roofing & General Contractors, and I’ve guided countless San Antonio homeowners through metal roof patch repairs that have prevented costly water damage and extended the life of their roofs. In this guide, I’ll walk you through the professional process we use to fix metal roof leaks correctly the first time.

When and Why a Metal Roof Patch is Needed

Think of a metal roof patch as emergency surgery for your roof—a targeted fix that stops a small problem before it becomes a major disaster. When you catch damage early and patch it properly, you’re protecting everything underneath: your belongings, your family, and the structural bones of your home.

The truth is, even a tiny hole in your metal roof can turn into a nightmare. Water doesn’t just drip straight down—it travels along roof decking, seeps into insulation, and eventually shows up as a stain on your ceiling. By that time, you might already have mold growing in your walls or rot spreading through your framing. The EPA’s guide on mold and moisture makes it clear: once mold takes hold, you’re looking at both health risks and serious repair bills.

A well-applied metal roof patch stops this chain reaction in its tracks. For homeowners in San Antonio who need reliable metal roof repair, addressing small issues quickly is the smartest investment you can make.

Common Causes of Metal Roof Damage

Metal roofs are tough—they can last half a century or more—but they’re not invincible. Here in Texas, our roofs take a beating from weather that swings from scorching summers to sudden hailstorms.

Weather exposure is the biggest culprit. Hail can punch holes straight through metal panels, especially if it’s large and wind-driven. High winds don’t always tear off panels, but they can work fasteners loose over time, creating gaps where water sneaks in. Heavy rains just wait for these opportunities to cause trouble.

Falling tree branches are another common problem. One good storm, and a branch comes down hard enough to dent or puncture your roof. Even smaller debris can scratch the protective coating, which opens the door to rust down the line.

Here’s something many homeowners don’t realize: improper installation causes a surprising number of leaks. When screws are over-tightened, they compress the rubber washer too much and it fails early. When they’re under-tightened, the seal never forms properly. Either way, as the metal expands and contracts with temperature changes, those fasteners back out and create leak points.

Age-related deterioration is inevitable. Sealants break down after years of UV exposure. Protective coatings wear thin. Small amounts of rust appear, especially around fasteners or where the coating was scratched during installation or maintenance.

Foot traffic might seem harmless, but walking carelessly on a metal roof or dropping tools can create dents or punctures that need patching. And poor attic ventilation can cause condensation to form on the underside of your metal panels, leading to corrosion you can’t even see until it’s serious.

Identifying Damage That Requires a Patch

Not every roof problem needs a full replacement. The key is knowing when a metal roof patch will do the job and when you need to call in the professionals for something bigger.

Visible holes are the most obvious sign—especially small punctures under three inches from hail or debris impact. These are perfect candidates for patching if you catch them early.

Leaks and water stains on your ceiling or walls mean water is getting in somewhere above. Sometimes the leak shows up far from the actual damage point because water travels along roof decking before dripping down. Either way, it’s time to investigate.

Rust and corrosion that’s localized to small spots can often be treated and patched. You’ll need to remove the loose rust, apply a rust-inhibiting primer, and then patch over it. If you’re seeing widespread rust across multiple panels, though, your roof might be telling you it’s nearing retirement.

Loose or missing fasteners create direct pathways for water. The good news is these are usually easy fixes—you can replace the fastener and seal it properly with the right sealant.

Dents and punctures need attention even if they’re not leaking yet. A dent can compromise the protective coating, which means rust is coming. A puncture needs immediate repair.

Gaps around flashing—those metal pieces around vents, chimneys, and skylights—are common trouble spots. The sealant degrades over time, and suddenly you’ve got water coming in around your bathroom vent. A fresh application of sealant or a small patch often solves this.

Separated seams on older metal roofs can sometimes be resealed, especially if the separation is minor and localized.

Here’s the bottom line: a metal roof patch works beautifully for small, localized damage. But if you’re seeing widespread rust, multiple large holes, significant buckling, or structural problems, it’s time for a professional assessment. We’ve seen homeowners try to patch their way out of problems that really needed comprehensive repair, and it never ends well. When in doubt, get expert eyes on it—that’s what we’re here for.

Gearing Up: Tools and Materials for Your Patch Project

Before you even think about climbing onto your roof, proper preparation is key. Having all your tools and materials ready will make the job safer, more efficient, and ultimately lead to a better repair. We want to ensure you’re fully equipped to tackle your metal roof patch project with confidence.

Essential Tools

A successful metal roof repair requires a combination of common household tools and a few specialized items. Let’s start with the most important category: safety gear. This is absolutely non-negotiable. You’ll need a sturdy ladder that’s rated for your weight plus your tools, and a safety harness is essential for steep roofs or if you’re uncomfortable with heights. OSHA provides important guidelines for protecting roofing workers, which are valuable even for homeowners tackling DIY projects. Don’t forget safety glasses to protect your eyes from debris and chemicals, thick gloves to shield your hands from sharp metal edges and sealants, and non-slip shoes for crucial traction on a potentially slick roof surface.

For cleaning and preparation, you’ll need a wire brush or sandpaper for removing rust, loose paint, and debris. A degreasing cleaner like Simple Green or mineral spirits ensures a clean, oil-free surface, and you’ll want clean rags or cloth for wiping and drying.

When it comes to cutting and shaping your patch, tin snips or metal shears are essential for cutting your patch material, along with a measuring tape for accurate measurements. For application and fastening, grab a caulking gun for applying sealants, a drill with screw bits for securing screws, a putty knife for smoothing sealants and removing excess, and a screwdriver for tightening loose fasteners.

Choosing the Right Materials

The longevity and effectiveness of your metal roof patch hinge significantly on the materials you choose. It’s not just about covering the hole—it’s about creating a durable, watertight seal that can withstand San Antonio’s temperature swings and weather extremes.

For the patch itself, you’ll want sheet metal that matches your roof’s material and gauge as closely as possible. This could be galvanized steel, aluminum, or another metal depending on your existing roof. The patch should be large enough to overlap the damaged area by at least 2 inches on all sides.

Your sealant choice is critical. Urethane or silicone sealant specifically formulated for metal roofs provides the flexibility needed to accommodate thermal expansion and contraction. Cheaper alternatives might save you a few dollars now but will likely fail prematurely, costing you more in the long run.

You’ll also need self-tapping roofing screws with neoprene washers to secure the patch without creating new leak points. These screws are designed to drill their own pilot holes and compress the washer for a weathertight seal.

Before applying your patch, treat any rust with a rust-inhibiting primer. This step is crucial for preventing corrosion from spreading underneath your new patch. Finally, consider getting matching roof paint to protect the patch and blend it with your existing roof, both for aesthetics and added weather protection.

The right materials might cost a bit more upfront, but they’re the difference between a patch that lasts for years and one that fails after the next heavy rain.

If you’re facing a tricky repair or want the assurance of a professional job, don’t hesitate to reach out. We provide free estimates for all our work. Call us at (726) 727-7663 for a free inspection and let our experts ensure your roof is secure.