Why Winter Asphalt Shingle Installation Is More Common Than You Think

Installing asphalt shingles in winter is not only possible but happens more frequently than most homeowners realize. While many people assume roofing work stops when temperatures drop, the reality is quite different – especially here in San Antonio where winter weather can be unpredictable.

Quick Answer: Can You Install Asphalt Shingles in Winter?

- Yes, it’s feasible – with proper precautions and techniques

- Minimum temperature: 40°F (4°C) for safe installation

- Key requirements: Warm storage, hand-sealing, adjusted tools

- Best conditions: Clear, dry days with temperatures above 40°F

- Professional expertise: Essential for warranty compliance and safety

The truth is, more than 5 million homes get new roofs installed each year in the United States, including during cold weather months. As one industry expert put it: “Contrary to popular belief, cold weather does not necessarily signal the end to roofing season.”

Why would anyone attempt winter installation? Sometimes it’s unavoidable. Storm damage doesn’t wait for spring, and a leaking roof in freezing temperatures can cause thousands of dollars in water damage. Other times, it’s simply about timing – contractor availability, project schedules, or taking advantage of off-season pricing.

The challenge isn’t whether it can be done, but whether it should be done – and if so, how to do it right. Asphalt shingles become brittle below 40°F, self-sealing strips won’t activate properly, and standard installation techniques need major adjustments.

For San Antonio homeowners, our relatively mild winters create unique opportunities. While we might see temperatures drop into the high 20s°F overnight, midday highs often climb back into the 40s°F – creating workable installation windows that northern climates simply don’t have.

I’m Carlos Yzaguirre, President of Apex Roofing & General Contractors, and I’ve overseen countless winter roofing projects across San Antonio and the Hill Country. Through years of experience installing asphalt shingles in winter conditions, I’ve learned that success depends entirely on understanding material behavior, proper techniques, and knowing when to wait for better weather.

Handy installing asphalt shingles in winter terms:

- asphalt shingles installation

- replacing asphalt shingle roof

- replacing asphalt shingles with metal roof

Winter Roofing Reality Check: Temperature Limits & Material Behavior

Let’s get real about what happens when you’re installing asphalt shingles in winter. The science isn’t rocket science, but it’s absolutely critical to understand if you want your roof to last.

Think of asphalt shingles like a chocolate bar. Leave it in your car on a hot San Antonio summer day, and it becomes soft and gooey. Stick it in the freezer, and it becomes brittle and cracks when you try to break off a piece. Asphalt shingles behave exactly the same way.

The sweet spot for installing asphalt shingles is between 40°F and 85°F. Below 40°F, your shingles turn into that frozen chocolate bar – brittle and prone to cracking. Above 85°F, they become too soft and can be damaged just by walking on them.

Here’s something that might surprise you: according to the Asphalt Roofing Manufacturers Association (ARMA), asphalt shingles have been successfully installed in cold climates for over one hundred years. The key word here is “successfully” – it takes the right techniques and expertise.

Why Temperature Matters

When that thermometer drops below 40°F, your shingles go through some dramatic changes that can make or break your roof installation.

Flexibility loss is the biggest culprit. Cold asphalt becomes rigid, making shingles crack when you try to bend them around hips, ridges, and valleys. What would normally be a simple bend becomes a potential disaster.

Cracking risk multiplies exponentially. I’ve seen perfectly good shingles crack just from being handled or walked on in cold weather. Even dropping a bundle from truck height – something that wouldn’t faze a shingle in mild weather – can cause damage that compromises the entire installation.

The self-sealing strip issue is where things get really tricky. Most asphalt shingle roofs include thermally activated sealant strips that bond adjacent shingles together. These strips need heat from sun exposure to activate properly. In cold weather, this process can stretch from days to several weeks.

Adhesive activation delays can leave your roof vulnerable to wind uplift for extended periods. If temperatures stay consistently below 40°F without sufficient direct sunlight, those sealant strips may not activate at all until spring arrives.

Minimum & Ideal Installation Windows

That 40°F threshold isn’t some arbitrary number pulled out of thin air. It’s based on decades of field testing and material science. Even in Canada, where cold-weather roofing is a way of life, the minimum recommended installation temperature is 4°C (40°F).

But here’s where San Antonio’s climate gives us an advantage. Even when our morning air temperatures hover around 40°F, roof deck temperatures can be significantly warmer due to heat transfer from inside the building, solar radiation absorption by dark roof surfaces, and the thermal mass of the roof structure itself.

This creates installation windows that northern climates simply don’t have. The key is monitoring both air and surface temperatures throughout the day. What starts as a marginal morning can turn into ideal installation conditions by noon.

At Apex Roofing & General Contractors, we’ve learned to read these temperature patterns like a weather map. It’s part of what makes us the go-to roofing experts in San Antonio and the Hill Country – we know when conditions are right and when they’re not.

Installing Asphalt Shingles in Winter: Step-by-Step Best Practices

Installing asphalt shingles in winter isn’t just about putting on extra layers and hoping for the best. It requires a complete rethink of every step in the process. After years of working on asphalt shingle roofs during San Antonio’s unpredictable winter weather, we’ve learned that success comes down to methodical preparation and adjusted techniques.

The reality is that cold weather changes everything about how materials behave and how safely crews can work. What works perfectly in July can be a disaster in January. That’s why we’ve developed a systematic approach that accounts for every variable winter throws at us.

Site & Safety Prep in Freezing Temps

Winter roofing safety goes way beyond the standard OSHA fall protection requirements we use year-round. Cold weather creates hazards that simply don’t exist in warmer months, and preparing for them can mean the difference between a successful project and a dangerous situation.

Improved fall protection becomes critical when temperatures drop. We use winter-rated harnesses and equipment specifically designed to function in cold conditions. Standard equipment can become brittle and fail when it’s really cold – something you definitely don’t want to find while you’re 20 feet up.

Specialized footwear with improved traction is absolutely essential. Even a light frost can turn a roof surface into an ice rink. We’ve seen too many close calls to take chances with regular work boots.

The roof surface must be completely clear of snow, ice, and frost before any installation begins. We use non-abrasive removal methods to avoid damaging existing materials. It might seem obvious, but you’d be surprised how many problems start with someone thinking they can work around a little ice.

Worker warm-up breaks aren’t just about comfort – they’re about safety. Cold weather affects dexterity and judgment, and hypothermia can sneak up on even experienced roofers. We schedule regular breaks and keep a close eye on our crew members throughout the day.

Winter’s shorter daylight hours naturally limit our work time, but we also factor in the slower pace required for safe cold-weather installation. Rushing in cold weather is a recipe for accidents and poor workmanship.

For homeowners dealing with emergency situations, our roof repair services include temporary weatherproofing to protect your home while we wait for suitable installation conditions.

Handling & Storing Shingle Bundles

This is where many winter roofing projects go wrong before they even start. Cold shingles are completely unforgiving – one wrong move can crack an entire bundle and turn expensive materials into expensive waste.

Indoor warming is non-negotiable. We store shingle bundles in heated areas for at least 24 hours before installation. This keeps them above 70°F and maintains the flexibility needed for proper handling. It’s not convenient, but it’s absolutely necessary.

Flat stacking might seem like a small detail, but it’s crucial. Shingle bundles retain the shape of whatever surface they’re stored on when cold. Store them on an uneven surface, and you’ll create permanent ripples that make installation difficult or impossible.

We always use pallet elevation to keep bundles off the ground. Moisture can wick up from concrete or dirt and freeze, causing bundles to stick together. Separating frozen bundles without damage is nearly impossible.

Tarp coverage protects against even brief exposure to precipitation. Frozen bundles that stick together are a nightmare to work with. We cover all materials with waterproof tarps and secure them against wind – San Antonio’s winter winds can be surprisingly strong.

The golden rule for cold weather is never bend, throw, or drop shingle bundles. What might cause minor damage in summer can completely destroy shingles in winter. Every movement needs to be deliberate and gentle.

Installing Asphalt Shingles in Winter: Hand-Sealing Techniques

When installing asphalt shingles in winter, hand-sealing becomes your best friend because those thermal-activated sealant strips just won’t work reliably below 40°F. This extra step takes time and adds cost, but it’s absolutely essential for a roof that won’t blow off in the first strong wind.

Asphalt roofing cement is the key to proper hand-sealing. We apply a dab under each shingle tab that’s about the size and thickness of a quarter. Too little and you won’t get a proper seal. Too much and you’ll create unsightly blistering that can actually weaken the roof.

For three-tab shingles, we apply three spots of cement. For architectural shingles, we use three evenly spaced spots along the seal line. This three-spot rule comes directly from ARMA recommendations, and we follow it religiously in cold-weather installations.

Eave and rake areas get special attention because wind uplift forces are strongest there. These edges are most vulnerable when thermal sealing is delayed, so we’re extra careful with cement application in these critical zones.

The hand-sealing process adds time and labor cost to the project, but it’s the difference between a roof that performs properly and one that fails the first time we get a strong storm.

Tool Adjustments When Installing Asphalt Shingles in Winter

Your trusty roofing tools that work perfectly in summer become temperamental in cold weather. Everything needs adjustment, and having backup plans is essential.

Compressor PSI adjustments are critical because cold air in pneumatic lines reduces nail gun velocity. We increase compressor pressure and frequently check nail penetration depth to ensure proper fastening. Under-driven nails are just as bad as over-driven ones.

Hose insulation prevents pneumatic lines from freezing in extreme cold. Frozen hoses mean tool failure, which means work stoppage. We use insulated hoses and keep equipment warm between uses.

When temperatures drop below 40°F, we often switch to manual nailing to ensure proper nail placement and prevent blow-through in brittle shingles. It’s slower, but it’s more reliable than fighting with finicky pneumatic tools.

Ridge cap pre-warming is essential because these pieces require significant bending during installation. We pre-warm ridge cap shingles to prevent cracking during application. It’s one more step, but it prevents costly callbacks and warranty issues.

Common Pitfalls & How to Avoid Them

I’ve been installing asphalt shingles in winter across San Antonio and the Hill Country for years, and I can tell you that the same mistakes happen over and over again. The good news? They’re all preventable when you know what to watch for.

The biggest mistake I see is cracked shingle installation. It’s tempting to think a small crack won’t matter, but in cold weather, that tiny crack becomes a spider web of damage within weeks. Cold makes cracks grow faster than you’d believe. We never install a cracked shingle – period. It’s better to warm up a replacement piece than deal with callbacks later.

Over-driven nails are another winter nightmare. When shingles are brittle, nail guns can punch right through them like paper. We’ve learned to check nail depth constantly and adjust compressor pressure throughout the day as temperatures change. What worked at 9 AM might be too much force by noon when the roof deck warms up.

Here’s something that drives me crazy: pallet ripples. These happen when shingle bundles are stored on uneven surfaces overnight. The shingles literally freeze into that wavy shape, making them nearly impossible to install flat. We always store bundles on level pallets and check them before bringing them up to the roof.

Unsealed tabs are probably the most expensive mistake homeowners face. Some contractors skip hand-sealing because “they’ll seal up in spring.” That’s like leaving your front door open uped because you’ll remember to lock it later. One good windstorm before those tabs seal naturally, and you’re looking at major damage. We hand-seal every tab, every time.

Warranty issues can be tricky with winter installations. Some manufacturers try to exclude damage that happens before sealant strips activate naturally. That’s why proper hand-sealing isn’t just good practice – it’s warranty protection. We document our hand-sealing process to prevent any warranty disputes down the road.

Dust on seal strips is a sneaky problem in windy conditions. Dust settles on the sealant before it can activate, creating a barrier that prevents proper bonding. We clean strips before applying roofing cement, especially on windy days.

The truth is, most of these problems stem from rushing the job or not adjusting techniques for cold weather. That’s why our roof inspections include checking for these specific winter installation issues. Catching problems early saves thousands in repair costs later.

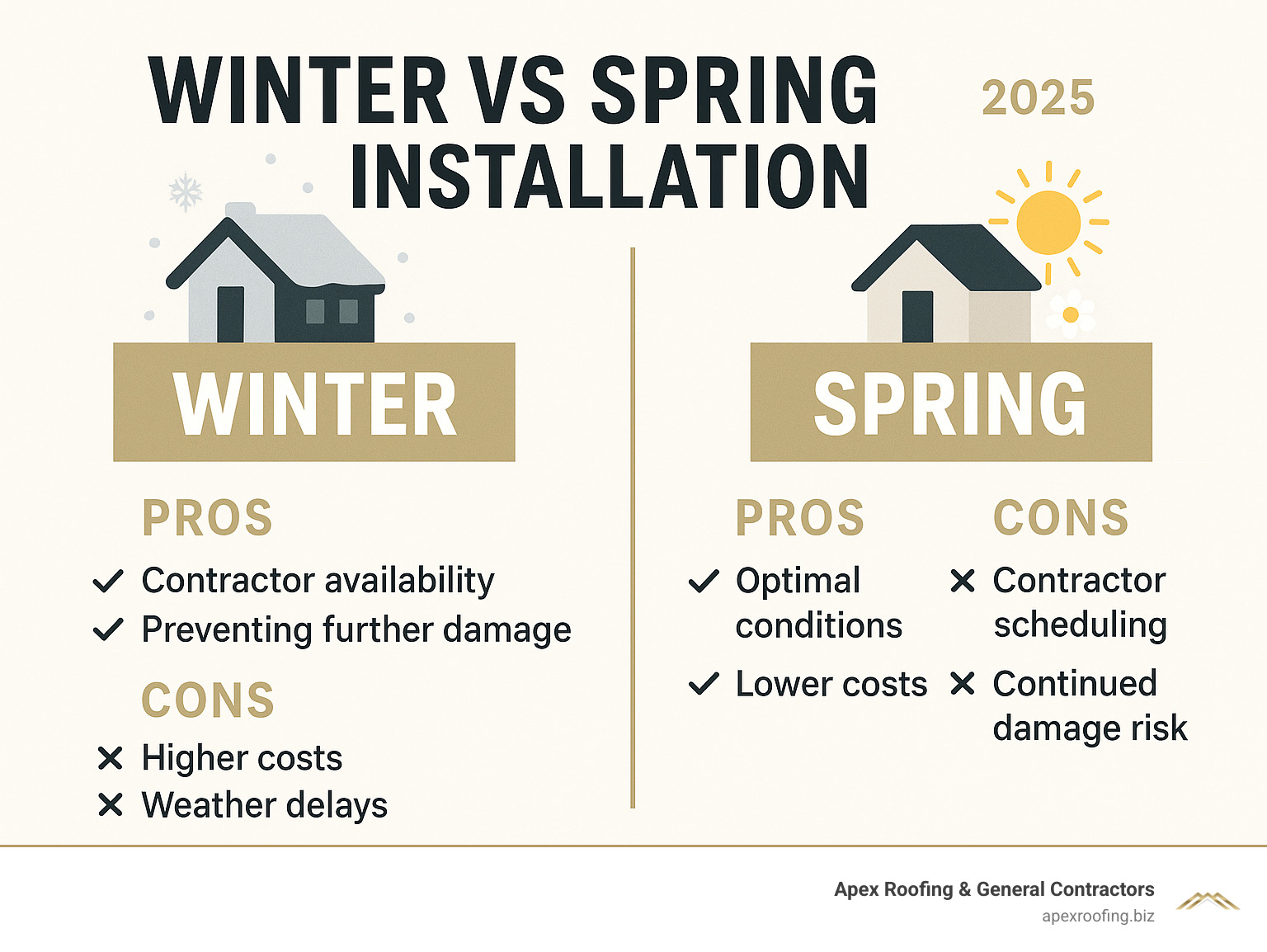

Homeowner Decision Guide: Install Now or Wait for Spring?

Deciding whether to proceed with installing asphalt shingles in winter or wait for warmer weather is one of the toughest calls San Antonio homeowners face. After helping hundreds of families through this decision over the years, I can tell you there’s no one-size-fits-all answer – but there are clear factors that make the choice easier.

When waiting isn’t an option, the decision makes itself. If your roof is actively leaking or you’ve suffered significant storm damage, every day you wait means more water damage inside your home. I’ve seen minor leaks turn into major structural problems in just a few weeks of winter weather. Water doesn’t take a break for spring, and neither should your repairs.

Ice dam prevention is another urgent concern, especially in areas of San Antonio that experience freezing temperatures. Proper installation of ice and water barriers can prevent thousands of dollars in damage. While our winters are generally milder than northern climates, those occasional hard freezes can create serious problems for vulnerable roofs.

Sometimes the smartest approach is a temporary solution followed by proper installation when conditions improve. Our emergency roofing services can provide weatherproofing that protects your home through winter while we plan for optimal installation conditions in spring.

Project costs are definitely higher in winter – typically 10-20% more due to additional precautions, slower work pace, and specialized techniques required for cold-weather installation. However, this cost increase must be weighed against the ongoing damage from waiting. I’ve seen homeowners save a few thousand on installation costs only to spend much more on interior water damage repairs.

Contractor availability is actually one of winter’s biggest advantages. During peak season, the best roofing contractors in San Antonio are often booked months in advance. Winter gives you access to top-quality crews who might be impossible to schedule during busy spring and summer months.

Energy loss from a damaged roof can be substantial during heating season. San Antonio winters might be mild compared to northern states, but we still see heating bills spike when roofs aren’t properly sealed. The energy savings from proper installation often offset much of the additional winter installation costs.

Property protection goes beyond just the roof structure. Water intrusion can damage interior finishes, personal belongings, and create conditions for mold growth. The cost of protecting your home’s interior often exceeds the premium for winter installation.

The reality is that every situation is unique. A small leak on a newer roof might be manageable with temporary repairs, while extensive storm damage requires immediate attention regardless of weather. Our roof inspection services can help assess your specific situation and provide the information you need to make the best decision for your home and budget.

Frequently Asked Questions about Cold-Weather Shingle Installation

Let’s address the most common questions we get from San Antonio homeowners about installing asphalt shingles in winter. These concerns come up on almost every winter roofing consultation.

Can asphalt shingles really seal in winter?

This is probably the biggest concern homeowners have, and it’s a valid one. Yes, asphalt shingles can seal in winter, but it takes much longer than in warm weather and requires proper hand-sealing for immediate protection.

The thermal activation process depends on several factors: temperature, sun exposure, and roof orientation. A south-facing slope with good sun exposure will seal much faster than a north-facing slope that stays in shadow most of the day.

Here’s what actually happens: the sealant strips will eventually activate once temperatures consistently reach 40°F and there’s adequate sunlight. However, this process can take several weeks in winter conditions instead of the typical few days in summer.

That’s why hand-sealing with asphalt roofing cement is so crucial during winter installation. It provides immediate wind resistance until thermal sealing occurs naturally. Think of it as insurance – you’re not waiting for Mother Nature to cooperate with your roof’s protection.

What is the lowest safe temperature for installation?

While there’s no absolute lower limit set in stone, practical installation becomes extremely difficult below 40°F. We’ve successfully completed projects at temperatures as low as 32°F, but only under ideal conditions with extensive precautions.

The key factors that determine whether installation is safe include shingle storage temperature (they must be kept warm), roof deck temperature (which can be warmer than air temperature due to heat from inside the building), wind conditions (wind chill affects material handling), and crew experience with cold-weather techniques.

What many homeowners don’t realize is that the roof surface itself can be significantly warmer than the air temperature. Heat transfer from inside the building, solar radiation on dark surfaces, and thermal mass all contribute to creating workable conditions even when it’s chilly outside.

Does winter installation affect my manufacturer warranty?

This is a great question that puts many homeowners’ minds at ease. No, winter installation doesn’t void manufacturer warranties if proper techniques are followed. However, most manufacturers exclude damage that occurs before sealant activation – which is exactly why proper hand-sealing is so important.

GAF, one of the major manufacturers, specifically states: “There is no practical lower or upper temperature limit governing when asphalt fiberglass shingles may be applied, as long as appropriate precautions are taken.”

The key is following manufacturer guidelines for cold-weather installation and documenting that proper techniques were used. When you work with experienced contractors who understand these requirements, your warranty remains fully intact.

At Apex Roofing & General Contractors, we’ve been handling winter installations across San Antonio and the Hill Country for years. We know exactly what manufacturers require and document every step to protect your investment—whether it’s a family home or a commercial roofing asset. If you’re facing a winter roofing decision, reach out to our San Antonio roofing experts for a free estimate and honest assessment of your situation.

Conclusion

Installing asphalt shingles in winter doesn’t have to be a homeowner’s nightmare. With the right knowledge and experienced professionals, it can be done safely and effectively – even here in San Antonio where our weather can surprise us.

The truth is, winter roofing is more common than most people think. When storm damage strikes or urgent repairs can’t wait for spring, proper cold-weather installation techniques make all the difference. The key is understanding that everything changes below 40°F – from how materials behave to how tools perform.

As we’ve covered, successful winter installation requires warm storage of materials, hand-sealing techniques, adjusted tool settings, and most importantly, experienced crews who understand these critical differences. Skip any of these steps, and you’re asking for trouble.

For San Antonio homeowners, our relatively mild winters actually create opportunities that northern climates don’t have. Those sunny winter days when temperatures climb into the 40s°F? That’s when experienced contractors can work magic, protecting your home while taking advantage of better contractor availability and off-season scheduling.

At Apex Roofing & General Contractors, we’ve spent years perfecting our winter installation methods. Our certified crews know exactly when conditions are right for installation and when it’s better to wait. We’ve seen too many botched winter jobs from contractors who thought they could wing it – and we’ve fixed plenty of them too.

Whether you’re dealing with emergency storm damage that can’t wait or you’re planning ahead to secure top-quality contractors during the slower season, we’re here to help. Our approach to roof installation in winter conditions has been refined through countless projects across Bexar County.

Don’t let winter weather leave your home vulnerable to the elements. We provide free estimates and honest assessments about whether your situation requires immediate attention or can safely wait for better conditions. Sometimes the best advice is to wait – and we’re not afraid to tell you that.

Ready to protect your home this winter? Contact us at (726) 727-7663 to schedule your free inspection and estimate. As San Antonio’s go-to roofing experts, we’re here to ensure your roof installation is done right, regardless of what Mother Nature throws at us.