Why EPDM Roof Maintenance Is Critical for Your Property Investment

EPDM roof maintenance is essential for protecting one of your most valuable investments. This synthetic rubber membrane—made from Ethylene Propylene Diene Monomer—can last up to 50 years with proper care, but as any experienced Texas roofing contractor knows, neglect can cut that lifespan in half.

Essential EPDM Maintenance Tasks:

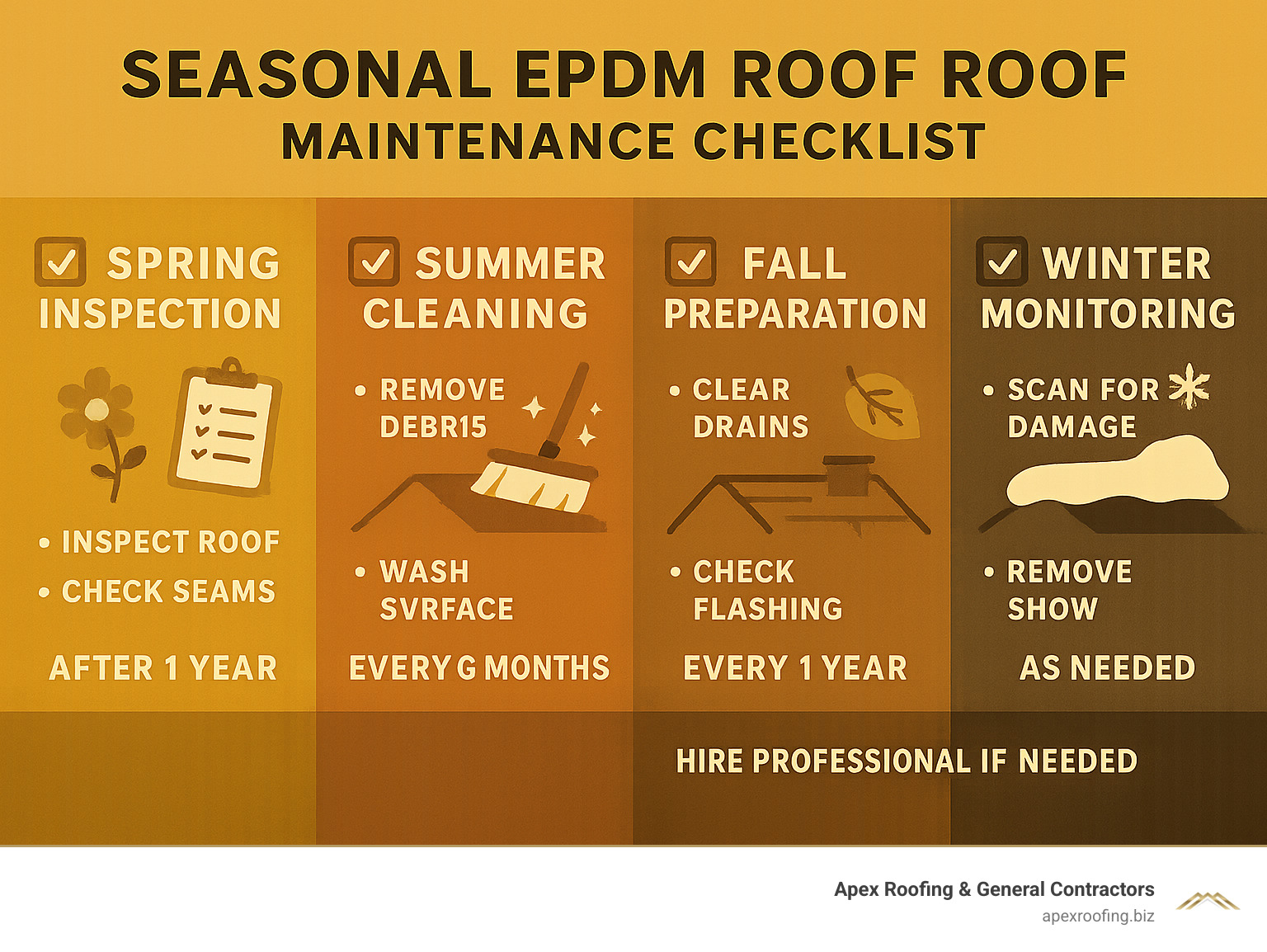

- Inspect twice yearly (spring and fall) plus after severe weather

- Clean regularly with mild soap and soft brushes—avoid petroleum-based cleaners

- Check seams and flashing for gaps, shrinkage, or adhesive failure

- Remove debris from roof surface and drainage systems promptly

- Address ponding water within 48 hours to prevent membrane damage

- Repair punctures immediately using proper EPDM patches and sealants

EPDM roofing offers exceptional durability and weather resistance, making it ideal for Texas climates. However, even the toughest materials need regular attention to maintain their protective qualities. Proper maintenance prevents small issues from becoming costly replacements and ensures your commercial roofing services investment delivers maximum value.

Regular care protects against common problems like seam failures, membrane shrinkage, and punctures from debris or foot traffic. With consistent upkeep, your EPDM system will continue providing reliable protection for decades.

As Carlos Yzaguirre, President of Apex Roofing & General Contractors, I’ve seen how proper EPDM roof maintenance can extend system life well beyond industry averages while preventing emergency repairs. Our team has helped countless San Antonio property owners maximize their roofing investments through proactive maintenance programs.

The Essentials of EPDM Roof Care

Think of your EPDM roof like your carit runs beautifully when you keep up with regular maintenance, but skip those check-ups and you’ll face expensive problems down the road. EPDM roof maintenance centers around four key areas: consistent inspections, thorough cleaning, debris removal, and keeping your drainage systems flowing smoothly. While EPDM is famous for being low-maintenance, ignoring these basics in San Antonio’s ever-changing weather can shorten your roof’s life significantly.

The secret to successful EPDM care lies in staying ahead of problems rather than reacting to them. Regular attention to your gutters prevents water backup, while prompt debris removal stops moisture from getting trapped against your membrane. Most importantly, maintaining clear drainage systems prevents ponding waterone of EPDM’s biggest enemies.

When drainage fails, water sits on your roof for more than 48 hours, which can weaken the membrane and create leak points. For comprehensive guidance on seasonal roof preparation, check out our tips on getting your commercial roof ready for spring in Austin, which applies to EPDM systems throughout Texas.

The Core of Your EPDM Roof Maintenance Plan: Inspections & Cleaning

Your roof needs regular check-ups just like you do! We recommend bi-annual inspectionsonce in spring to assess winter damage and again in fall to prepare for colder months. Think of these as your roof’s wellness visits. Beyond these scheduled inspections, always check your roof after severe weather events like hailstorms or high winds, which are common visitors to our San Antonio area.

During these visual checks, look for anything unusual: small tears, punctures, lifted seams, or areas where water collects. Also watch for biological growth like algae or moss, which love damp conditions and can damage your membrane over time.

Cleaning your EPDM roof keeps it healthy and helps you spot problems early. While EPDM doesn’t get as dirty as other roofing materials, accumulated debris traps moisture and can hide underlying issues. Your cleaning toolkit should include a soft-bristle brush for gentle scrubbing and a leaf blower for removing loose debris.

For stubborn dirt, mix mild soap and watersimple dish soap works perfectly. Apply the solution, gently scrub, then rinse thoroughly with clean water. This routine not only keeps your roof looking professional but also maintains its protective qualities.

However, here’s where many property owners make costly mistakes. Certain cleaning products can seriously damage EPDM membranes:

- Petroleum distillates can cause swelling and deterioration

- Citrus cleaners break down the rubber compounds

- Harsh abrasives create tiny punctures that become big leaks

These chemicals can void your warranty and create expensive repair needs. Always stick to EPDM-specific cleaners or simple soap and water. For detailed cleaning techniques, this guide on How To Clean EPDM Rubber Roof provides excellent step-by-step instructions.

Don’t forget your gutter maintenance during cleaning sessions. Clogged gutters force water to back up onto your roof, creating the ponding water problems that can destroy EPDM membranes. Clear leaves, twigs, and debris from gutters and downspouts regularly to ensure proper water flow away from your building.

The Importance of Seam and Flashing Integrity

If your EPDM roof has an Achilles’ heel, it’s the seams and flashing. These areas where membrane sheets join together or seal around penetrations like vents, HVAC units, and skylights represent the most vulnerable points in your roofing system.

Over time, the adhesives holding EPDM seams together can dry out and weaken, creating tiny gaps that invite water infiltration. Membrane shrinkage compounds this problem as your roof ages, causing the material to pull away from sealed positions. You’ll notice this as tenting around parapet walls or wrinkling near penetrationsclear warning signs that your roof’s integrity is compromised.

Adhesive failure shows up as small separations along seam lines, while shrinkage creates larger gaps that need immediate attention. During every inspection, we focus on these critical areas, looking for lifting, cracking, or any signs of deterioration.

When we find issues, prompt action prevents small problems from becoming major leaks. The repair process involves thoroughly cleaning the affected area, applying compatible EPDM primer, then resealing gaps with high-quality lap sealant application. For larger separations, EPDM patches extending well beyond the damaged area ensure proper adhesion and long-lasting repairs.

Flashing around penetrations requires special attention because these complex areas naturally create potential entry points for water. Proper flashing installation and maintenance create watertight barriers that protect your building’s interior. We ensure EPDM extends correctly at these junctions and remains securely sealed against weather infiltration.

The goal is keeping every seam tight and every piece of flashing secure, preventing water from finding any path into your building. For comprehensive technical details on inspecting these critical components, the NACHI EPDM inspection guide offers valuable professional insights.

Regular attention to seam and flashing integrity can add decades to your roof’s life while preventing emergency repairs that disrupt your business operations.

Have questions or need help with EPDM roof maintenance? We give free estimatescall (726) 727-7663 to schedule a free inspection.

A Proactive Approach to EPDM Roof Maintenance and Problem Prevention

Think of EPDM roof maintenance like tending a garden—a little attention now prevents major headaches later. Rather than waiting for water stains on your ceiling to announce a problem, smart property owners stay ahead of common issues. EPDM roofing is incredibly tough, but even the strongest materials have their vulnerabilities. Understanding what can go wrong helps us keep things going right for decades.

The most common culprits we encounter include punctures from sharp debris or careless foot traffic, tears from weather stress or impact damage, and blisters that occasionally form when moisture gets trapped. Shrinkage is another long-term concern where the membrane gradually pulls away from edges and penetrations. And let’s not forget ponding water—standing water that lingers more than 48 hours can turn any small issue into a major problem by keeping your roof constantly saturated.

Identifying and Repairing Common Damage

Here in San Antonio, we see our fair share of hail damage and wind-driven debris that can puncture even the toughest EPDM membranes. Heavy foot traffic damage is another common issue, especially when maintenance crews aren’t careful about what they’re stepping on. The good news? Most of these problems are completely fixable when caught early.

During your inspections, watch for obvious holes or rips that are usually easy to spot. Surface abrasions or scuffs from debris rubbing against the membrane might seem minor but can worsen over time. Lifted or cracked seams signal adhesive failure or membrane shrinkage that needs immediate attention.

Areas of standing water indicate drainage problems or roof depressions that require professional assessment. Discoloration or excessive chalking beyond normal weathering can signal UV degradation. Bubbles or soft spots when you walk on the roof could mean trapped moisture or membrane separation—definitely worth investigating.

When repairs are needed, the process is straightforward but requires precision. First, we thoroughly clean the area to remove any dirt or debris that could interfere with adhesion. Next comes primer application—a thin, even coat that prepares the surface. The EPDM patch must extend at least two inches beyond the damaged area for proper coverage. Using a seam roller, we ensure complete contact and eliminate air bubbles. Finally, lap sealant around the patch edges provides extra protection against water infiltration.

This systematic approach creates repairs that often outlast the surrounding membrane. For a detailed visual guide, this video on how to patch an EPDM roof demonstrates professional techniques. Addressing small issues promptly prevents costly replacements down the road.

Managing Environmental Factors

Mother Nature can be both a friend and foe to your EPDM roof. Those beautiful Texas trees provide wonderful shade but can create ongoing maintenance challenges if not properly managed.

Tree maintenance deserves serious attention. Overhanging branches constantly drop leaves, twigs, and sometimes larger limbs onto your roof surface. This debris clogs gutters and drains, leading to ponding water issues. Branches scratch and abrade the membrane during windy conditions, while larger falling branches can puncture the surface entirely. Perhaps most problematic, trapped organic matter promotes biological growth by creating moist environments where algae and moss thrive.

We recommend trimming branches to maintain at least 10 feet of clearance from your roof. This simple step dramatically reduces debris accumulation and eliminates the constant rubbing that gradually wears down your membrane. It’s a small investment that pays huge dividends in roof longevity.

Algae and mold growth might seem like just a cosmetic issue, but these organisms can cause real problems. While EPDM itself resists biological growth, atmospheric dirt combined with shade and moisture creates perfect breeding conditions. Green algae patches or black mold streaks not only look unsightly but trap moisture against the membrane and make surfaces dangerously slippery.

Cleaning mold requires a gentle but thorough approach. Mild soap and water applied with soft-bristle brushes handles most situations effectively. For stubborn growth, we sometimes use diluted cleaning solutions, always testing in inconspicuous areas first and rinsing thoroughly afterward.

UV exposure effects develop gradually over decades, even with EPDM’s excellent UV resistance. Our intense Texas sun can eventually cause chalking or slight elasticity loss. This is perfectly normal aging, but it’s where periodic recoating becomes valuable for extending roof life. For comprehensive guidance on managing these environmental challenges, this resource on rubber roofing preventative cleaning and maintenance offers additional insights.

Staying ahead of environmental factors keeps your EPDM roof performing at its best, protecting your investment for the long haul.

Advanced Upkeep: EPDM Roof Restoration and Recoating

When your EPDM roof starts showing its age—maybe after 20 or 30 years of faithful service—you don’t necessarily need to panic about a complete replacement. EPDM roof maintenance can extend far beyond simple repairs into the field of restoration and recoating, strategies that can breathe new life into an aging roof system while saving you thousands of dollars.

Think of restoration as giving your roof a second chance. Instead of tearing off a roof that’s structurally sound but cosmetically tired, restoration can add another 10 to 20 years of reliable performance. It’s also a fantastic way to improve your building’s energy efficiency, especially here in San Antonio where our summers can be brutal on cooling costs.

The key is understanding when your roof is a good candidate for restoration versus when it needs more extensive work. A roof showing widespread chalking, minor surface cracks, or fading might be perfect for restoration, while one with significant leaks or saturated insulation likely needs replacement.

EPDM Roof Repair vs. Restoration

Here’s where many property owners get confused—when do you repair, and when do you restore? The difference is significant, both in scope and investment.

Repairs tackle isolated problems. When you have a puncture from a fallen branch or a small section of lifted seam, that’s repair territory. You’re addressing specific issues to stop leaks and maintain the integrity of those particular areas. It’s like fixing a flat tire—you patch the hole and keep rolling.

Restoration is a system-wide makeover. This approach treats your entire roof as needing attention, even if it’s not actively leaking everywhere. Maybe your EPDM has developed that telltale chalky surface, or the once-deep black color has faded to a dull gray. Perhaps you’re noticing minor surface cracking across large areas, or your energy bills have been creeping up as your roof absorbs more heat.

The scope difference is dramatic. While repairs focus on square feet, restoration covers your entire roof system. Yes, the initial investment is higher than patching a few spots, but it’s significantly less expensive than a complete tear-off and replacement. More importantly, restoration adds substantial life to your entire roof, not just the repaired sections.

Cost-wise, think of repairs as maintenance expenses—necessary but ongoing. Restoration is more like a major renovation that resets the clock on your roof’s lifespan. The goal shifts from “stop this leak” to “revitalize this entire system.”

Restoration works best when your roof shows widespread aging but minimal insulation saturation. If water has soaked through to your insulation extensively, restoration won’t solve the underlying moisture problems. However, if your roof deck and insulation are mostly dry, restoration can be incredibly effective.

The process involves extensive cleaning, completing any necessary minor repairs, and then applying a liquid coating over the entire surface. This creates a fresh, seamless membrane that bonds directly to your existing EPDM.

When and How to Recoat Your EPDM Roof

Recoating is the heart of most EPDM restoration projects, and recognizing when it’s needed can save you from premature roof replacement. Your roof will usually tell you when it’s time—you just need to know what signs to look for.

Significant fading is often the first clue. That rich black EPDM color starts looking tired and mottled. Excessive chalking becomes noticeable too—you’ll see a powdery residue that comes off when you touch the surface, indicating the membrane’s protective layers are breaking down. Minor surface cracking might appear as hairline fractures that don’t penetrate the membrane but show surface wear.

Here’s one sign many property owners miss: rising energy bills. An aged, dark EPDM roof can become a heat magnet, absorbing tremendous amounts of solar energy and making your HVAC system work overtime. This is where recoating really shines.

The benefits of recoating go well beyond aesthetics. You’re extending your roof’s lifespan by 10 to 20 years, postponing that expensive replacement far into the future. The liquid coating creates a seamless membrane that fills tiny imperfections and forms a monolithic, watertight layer over your entire roof.

Improved UV protection is another major advantage. Most modern coatings offer superior UV resistance compared to aged EPDM, protecting your underlying membrane from further sun damage. But perhaps the most compelling benefit in our Texas climate is the potential for a cool roof effect.

Light-colored coatings, particularly white silicone systems, can dramatically reduce your roof’s surface temperature by reflecting sunlight instead of absorbing it. We’ve seen roof temperatures drop by 40 degrees or more after recoating, which translates directly into lower cooling costs and improved indoor comfort.

Coating selection matters tremendously. Silicone coatings have become increasingly popular for EPDM restoration because of their excellent adhesion and remarkable resistance to ponding water—a common concern with flat roofs. These coatings can literally sit underwater for extended periods without degrading. Acrylic coatings are also available and can work well, though they’re generally not as durable in ponding water situations.

The application process requires meticulous attention to detail. Surface preparation is absolutely critical—the roof must be thoroughly cleaned to remove all dirt, debris, and chalking. Any existing damage gets repaired and fully cured before coating begins.

Depending on the coating system, a primer might be necessary to ensure optimal adhesion. The liquid coating then gets applied in multiple layers using rollers or spray equipment, with adequate drying time between each coat. The goal is achieving consistent thickness across the entire roof surface, including all flashing and penetrations.

When done properly, this process transforms a weathered, aging EPDM roof into a vibrant, high-performing system ready to handle another couple decades of whatever Mother Nature throws at it. It’s like giving your roof a complete makeover while keeping all the structural benefits of your original EPDM investment.

Frequently Asked Questions about EPDM Roof Maintenance

Property owners often reach out to us with thoughtful questions about caring for their EPDM roofs. After years of working with these durable systems across San Antonio, we’ve noticed certain concerns come up repeatedly. Let me share the answers to the most common questions we hear about EPDM roof maintenance.

How often should an EPDM roof be inspected?

Your EPDM roof deserves attention at least twice a year—once in spring and again in fall. Think of these as seasonal check-ups that help catch small issues before they become big headaches. Spring inspections let you assess any winter damage, while fall checks prepare your roof for the cooler months ahead.

Beyond these routine visits, we strongly recommend scheduling an inspection after severe weather events. San Antonio sees its share of hailstorms and high winds, and these can cause damage that isn’t immediately obvious from ground level. A post-storm inspection gives you peace of mind and helps document any insurance claims if needed.

These regular checks are your best defense against costly surprises. We’ve seen too many cases where a small tear or loose seam, left unnoticed for months, turned into a major leak that could have been easily prevented.

Can you walk on an EPDM roof?

Yes, you can walk on an EPDM roof, but it requires some common sense and caution. The membrane is surprisingly tough, but it’s not indestructible. Sharp objects stuck in shoe treads—like gravel or metal fragments—can puncture the surface. Even dropping a screwdriver or other tools can cause damage.

When we inspect EPDM roofs, we’re careful to wear soft-soled shoes and check our footwear beforehand. We also make sure the surface is completely dry, as wet EPDM can be slippery and dangerous to walk on.

If your building requires regular rooftop access for HVAC maintenance or other equipment, we recommend installing designated walkway pads. These protective strips distribute weight more evenly and prevent repetitive wear patterns that can weaken the membrane over time.

What is the average lifespan of a well-maintained EPDM roof?

This is where EPDM really shines. With proper installation and consistent EPDM roof maintenance, these systems regularly last 40 to 50 years. We’ve even seen some well-cared-for EPDM roofs exceed that range, still performing strong after decades of Texas weather.

The key phrase here is “well-maintained.” Regular cleaning prevents debris buildup that can trap moisture. Timely repairs of punctures or seam issues stop small problems from spreading. Periodic recoating refreshes the surface and adds years of additional protection.

Without this consistent care, even the best EPDM system can fail prematurely. We’ve replaced roofs that should have lasted decades longer, simply because they didn’t receive the attention they deserved. It’s a reminder that a little preventive care goes a long way in protecting your investment.

Maximize Your Investment with Professional EPDM Care

Your EPDM roof represents a significant investment in your property’s future, and EPDM roof maintenance is the key to protecting that investment for decades to come. Think of it this way: you wouldn’t skip oil changes on your car and expect it to run smoothly for 200,000 miles, would you? The same principle applies to your roofconsistent care today prevents expensive headaches tomorrow.

Throughout this guide, we’ve covered the essential elements of proper EPDM care: regular inspections twice yearly, thorough cleaning with appropriate materials, prompt repairs of punctures and seam issues, and proactive management of environmental factors like tree debris and ponding water. Each of these steps works together to create a comprehensive maintenance strategy that can extend your roof’s life well beyond the typical 40-50 year expectation.

The difference between proactive care and reactive repairs is often measured in thousands of dollars. A small puncture caught early might cost a few hundred dollars to fix professionally. That same puncture, left unattended, can lead to water damage, insulation replacement, and interior repairs that easily reach into the tens of thousands. It’s simple mathprevention wins every time.

While property owners can handle some basic maintenance tasks like debris removal and visual inspections, the value of professional expertise cannot be overstated. Our team brings specialized knowledge of EPDM systems, advanced diagnostic tools, and the experience to spot subtle warning signs that untrained eyes might miss. We understand how Texas weather affects these membranes and know exactly what to look for during different seasons.

For property owners in Texas, working with a certified commercial roofing company in San Antonio ensures your maintenance program meets local building codes and industry best practices. Our climate presents unique challengesfrom intense UV exposure to sudden hailstormsthat require specialized knowledge to address effectively.

At Apex Roofing & General Contractors, we’ve developed comprehensive maintenance plans custom to each property’s specific needs. These programs take the guesswork out of roof care, ensuring nothing falls through the cracks. We track inspection schedules, monitor potential problem areas, and provide detailed reports that help you make informed decisions about repairs and upgrades.

Don’t wait for a small issue to become a major expense. Our team is ready to help you develop a maintenance strategy that maximizes your roof’s lifespan and protects your property investment. For a free estimate on your EPDM roof needs, schedule a free inspection with our team. Let’s work together to keep your roof performing at its best for decades to come.