Why Asphalt Roll Roofing Installation Matters for Your Property

Asphalt roll roofing installation is a practical and budget-friendly solution for low-slope structures like sheds, garages, and covered patios. For property owners comparing roofing options, professional roofing installation services provide a reliable way to ensure the material performs as designed over its full lifespan. This type of roofing offers significant advantages for functional buildings where cost and speed of installation matter more than appearance. However, a successful installation depends on careful preparation and technique.

Quick Answer: Asphalt Roll Roofing Installation Basics

- Best For: Low-slope roofs (minimum 2:12 pitch), outbuildings, and functional structures.

- Cost: The least expensive roofing material available ($0.50-$1.50 per square foot).

- Lifespan: 5-8 years with proper installation.

- Installation Time: Can be completed in a single day for small structures.

- Key Requirements: Clean, dry deck; temperatures above 45-50°F; proper overlap and sealing.

- Not Suitable For: Flat roofs, primary residences, or steep slopes without modifications.

Roll roofing is similar to asphalt shingles but comes in 36-inch-wide rolls that cover about 100 square feet each, making it faster to install. However, its shorter lifespan and utilitarian appearance make it best for structures where function outweighs curb appeal, and it is not recommended for primary residences.

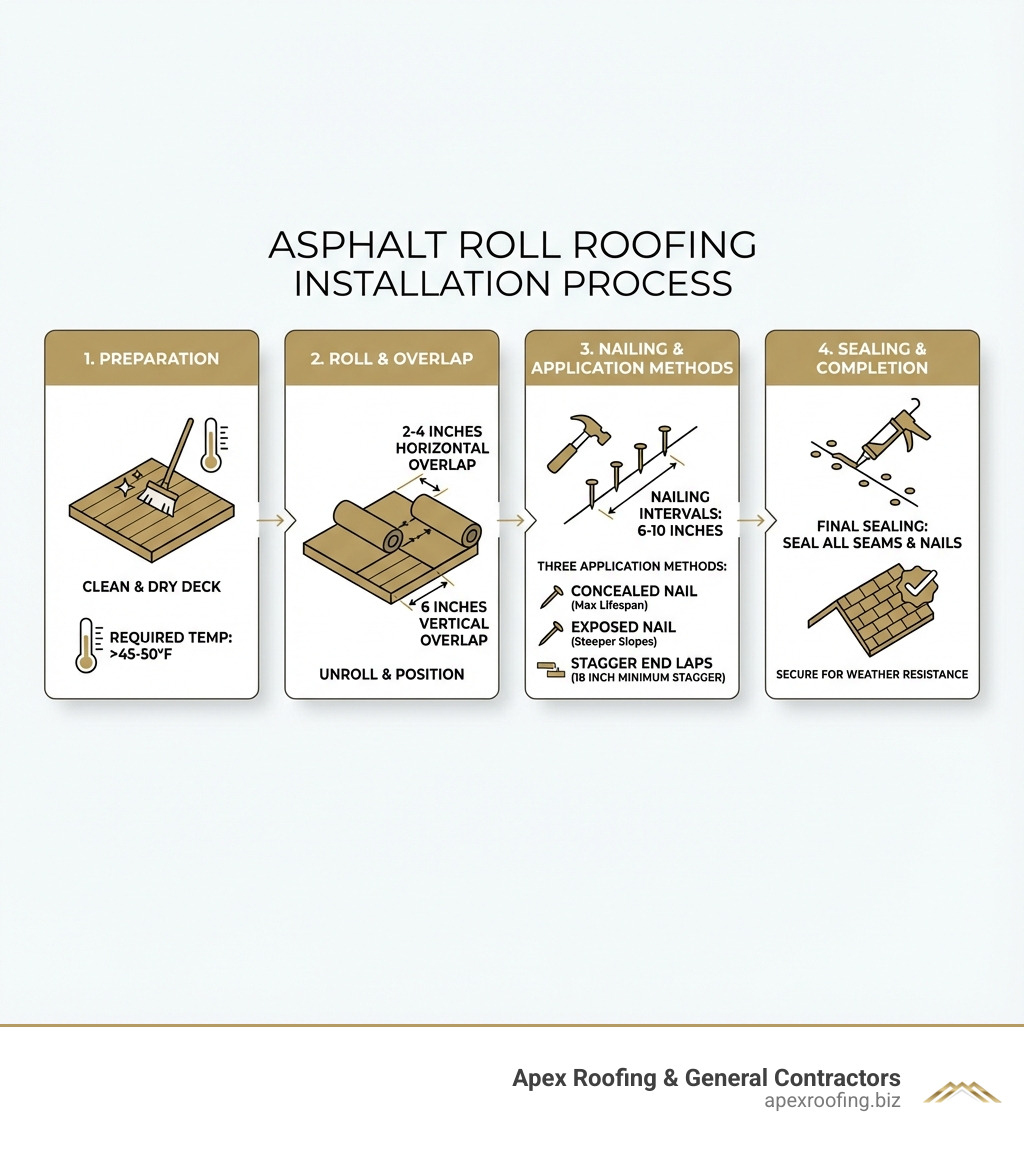

The installation process requires careful attention to temperature, deck preparation, overlap measurements, and sealing. Missing these steps can lead to premature failure.

I’m Carlos Yzaguirre, co-founder of Apex Roofing & General Contractors. Since 2022, I’ve guided many San Antonio homeowners through successful asphalt roll roofing installation projects. This guide will walk you through every critical step for a weather-tight, durable roof.

Understanding Rolled Roofing: Pros, Cons, and Ideal Uses

Asphalt roll roofing, also known as Mineral Surface Roll (MSR), is a composite material of asphalt-saturated felt or fiberglass topped with mineral granules. It is essentially a large, thin asphalt shingle sold in rolls, typically 36 inches wide and covering about 100 square feet. This format is ideal for certain structures in San Antonio and Bexar County that do not require the appearance or longevity of traditional shingles.

Compared to standard asphalt shingles which can last 20+ years, roll roofing is thinner, less durable, and has a shorter lifespan of five to eight years. Its primary advantage is cost-effectiveness, making it the least expensive roofing material for budget-conscious projects. The rolled format also allows for faster and easier installation, especially on smaller roofs.

However, these benefits come with trade-offs. The shorter lifespan means more frequent replacement, and its utilitarian look can negatively impact a home’s resale value. Homeowners’ associations in areas like Alamo Heights or Shavano Park may even prohibit its use on visible structures.

Key Characteristics of Rolled Roofing

Here are the distinct features of asphalt roll roofing:

- Material Composition: An asphalt-saturated organic felt or fiberglass mat, similar to shingles but manufactured in a continuous roll. Mineral Surface Roll (MSR) types have embedded surface granules for protection.

- Dimensions: Rolls typically cover 100 square feet (approx. 36 ft. long by 36 in. wide) and weigh around 72 pounds.

- Lifespan: Averages five to eight years, significantly less than the 20+ years expected from quality asphalt shingles.

- Cost-Effectiveness: It is the least expensive roofing material on the market, making it a major draw for functional projects.

- Aesthetics and Resale Value: Its functional appearance does not improve curb appeal or resale value and is often seen as a temporary solution.

This table provides a quick comparison:

| Feature | Rolled Roofing (Asphalt) | 3-Tab Asphalt Shingles |

|---|---|---|

| Cost (Material) | $0.50 – $1.50 per square foot | $1.00 – $2.00+ per square foot |

| Lifespan | 5-8 years | 15-20 years |

| Best Use | Low-slope outbuildings, sheds | Residential homes, moderate slopes |

| Installation Difficulty | Easier, faster for DIYers | Moderate, more time-consuming |

When to Choose Rolled Roofing

Asphalt roll roofing is best suited for specific applications:

- Functional Structures: Ideal for unoccupied buildings like sheds, detached garages, workshops, and barns where low cost is prioritized over aesthetics.

- Low-Slope Residential Additions: An effective, economical solution for covered patios or additions with a low roof pitch.

- Minimum Roof Pitch: It is designed for low-slope roofs with a minimum pitch of 2:12 (2 inches of fall per 12 inches of run). It can be used on slopes down to 1:12 with the concealed nail method. Rolled roofing must not be used on flat roofs, as standing water will cause leaks and premature failure.

- Not for Primary Residences: We strongly advise against using roll roofing on a main home due to its short lifespan and negative impact on property value. For residential homes in areas like Helotes and Leon Valley, more durable options like asphalt shingles are recommended. Our Roofing Installation Service Guide offers more insight into various materials.

Gearing Up: Essential Tools and Pre-Installation Prep

Proper preparation is paramount for a successful asphalt roll roofing installation. Gathering the right tools and prepping the roof deck correctly ensures a durable, weather-tight result.

Necessary Tools and Materials

Organize your supplies before you begin for a smoother, safer process.

- Tools:

- Utility knife with extra blades

- Hammer

- Tape measure

- Chalk line

- Trowel (for cement application)

- Stiff-bristled broom

- Safety glasses and gloves

- Sturdy ladder

- Caulk gun (optional)

- Materials:

- Asphalt roll roofing

- Asphalt roofing cement (cold-application, ASTM D 3019 compliant)

- 1-inch galvanized roofing nails with wide heads

- Metal drip edge flashing

- Underlayment (optional but recommended for extra moisture protection)

Crucial Preparation for Your Asphalt Roll Roofing Installation

Do not skip these essential preparation steps:

- Clean the Roof Deck: Sweep the surface to remove all dirt, debris, and gravel. Anything left behind can puncture the new roofing.

- Secure Protruding Nails: Inspect the deck for old nails or fasteners. Hammer them down flush with the surface to prevent tears.

- Inspect and Repair Damage: Check for and repair any soft spots, rot, or damaged decking to ensure a solid base.

- Install Drip Edge: Install metal drip edge flashing along the eaves (horizontal edges) first, then along the rakes (sloped edges). This directs water away from the fascia.

- Install Underlayment (if using): Lay underlayment horizontally from the eaves up, overlapping courses by at least 2 inches and end laps by 4 inches for an added moisture barrier.

- Relax the Material: To prevent buckling, unroll the roofing and let it relax in a warm, sunny spot for at least a day before installation. Cutting it into 12- to 18-foot lengths can help.

- Work in Optimal Temperatures: It is critical to work in temperatures above 45-50°F (7-10°C). Cold weather makes the material brittle and prevents roofing cement from curing properly. For more on this, see our Tips for winter installations.

- Calculate and Purchase Materials: Measure your roof’s square footage to determine the number of rolls needed. Always purchase an extra 5-10% to account for waste, overlaps, and mistakes.

The Complete Step-by-Step Asphalt Roll Roofing Installation Guide

Now that we’ve gathered our tools and prepped the roof, it’s time for the main event: the asphalt roll roofing installation. This guide focuses on the concealed nail method for maximum service life and a clean finish.

Step 1: Marking Guidelines and Laying Underlayment

Accurate guidelines are essential for straight, evenly spaced courses.

- Install Underlayment (if applicable): If you decided to use underlayment, ensure it’s fully installed and smooth, with proper overlaps. This provides an additional layer of protection beneath your roll roofing.

- Snap Your First Chalk Line: For a straight first course, measure 35 inches up from the eaves and snap a chalk line across the roof’s width. This line marks the top edge of your first piece, ensuring a consistent overlap for subsequent courses. For more on this, see resources like How to Properly Install Roll Roofing .

Step 2: Cutting and Placing the First Course

- Cut Rolls to Manageable Lengths: Cut the roofing into manageable 12- to 18-foot sections. Varying the lengths helps stagger the end laps between courses.

- Apply Roofing Cement Along Eaves and Rakes: Before placing your first section, apply a continuous 1/8-inch thick layer of asphalt roofing cement along the eaves and rake edges over the drip edge.

- Position the First Course: Align the top edge of your first section with the chalk line. The bottom edge should overhang the drip edge by 1/4 to 3/8 inch.

- Smooth Out Wrinkles: Press the material flat against the deck and into the cement, working from the center out to remove air bubbles and wrinkles.

Step 3: Nailing and Sealing for a Secure Fit

This step creates the weather-resistant barrier. Use proper nailing and ample roofing cement.

- Nail the First Course (Concealed Nail Method):

- Lift the lower edge of your first course and apply a 2-inch wide band of roofing cement underneath.

- Press the edge firmly into the cement until a small bead squeezes out, indicating a good seal.

- Fasten the upper edge with 1-inch galvanized roofing nails. Place nails 1 inch from the top edge, spaced about 4 inches apart. These nails will be concealed by the next course.

- At the rake edges, cement and press the roofing down, then nail along the upper edge 1 inch from the side, with nails spaced 3 inches apart.

- Apply Roofing Cement for Overlap: Apply a 2-inch wide band of roofing cement along the top edge of the installed course to seal the overlap with the next course.

- Position and Nail Succeeding Courses:

- Measure 32-34 inches up from the top edge of the first course and snap a new chalk line.

- Align the second course with this line, creating at least a 3-inch overlap that covers the nails of the previous course.

- Press the course into the cement and repeat the nailing process: cement the lower edge, press down, and nail the upper edge.

- Stagger End Laps: Ensure end laps (where two sections meet) are offset by at least 18 inches from the laps in the course below. End laps should be 6 inches wide, fully cemented, and nailed securely.

- Repeat: Continue this process up the roof until it is fully covered.

Step 4: Finishing the Job: Sealing Edges and Nails

The final touches are crucial for waterproofing and ensuring the longevity of your asphalt roll roofing installation.

- Trim Excess Overhang: Use a utility knife to trim any excess material overhanging the rake edges for a clean line.

- Apply Roofing Cement to All Exposed Nail Heads: Apply a dab of roofing cement over any exposed nail heads to prevent water intrusion.

- Seal the Final Top Edge and All Seams: Apply a final bead of cement along the top edge of the last course and reinforce any vulnerable seams or T-joints (where side and end laps intersect).

- Final Inspection: Visually inspect all seams and edges, pressing down to ensure they are firmly adhered. Apply more cement to any loose spots.

By following these detailed steps, you’ll achieve a secure and weather-tight asphalt roll roofing installation. For professional assistance, you can View our professional roof installation services.

Common Mistakes, Maintenance, and Pro Tips

Knowing the common pitfalls of an asphalt roll roofing installation can prevent future headaches and leaks. Proper maintenance is also key to maximizing your roof’s lifespan.

Mistakes to Avoid During Your Asphalt Roll Roofing Installation

- Ignoring Temperature Warnings: Applying roll roofing below 45-50°F makes the material brittle and prevents the adhesive from curing correctly, leading to weak seals. Always plan your project for a warm day.

- Forgetting to Stagger Seams: Aligning end laps in adjacent courses creates a continuous weak point for water infiltration. Always offset end laps by at least 18 inches between courses.

- Inadequate Nailing or Skimping on Roofing Cement: The system’s integrity relies on both fasteners and adhesive. Use the correct nailing pattern (1 inch from edges, 4-6 inches apart) and apply a continuous 2-inch band of cement at all overlaps. Using too much cement can cause blistering.

- Not Preparing the Roof Deck Properly: Debris or protruding nails on the roof deck can puncture the new roofing. A clean, smooth surface is essential for proper adhesion.

- Using Roll Roofing on a Flat Roof: Roll roofing is for low-slope roofs, not flat ones. Without a minimum pitch (at least 1:12), water will pool and cause leaks.

For detailed manufacturer instructions, consult the product’s official guide, such as TAMKO’s Slate Surfaced Roll Roofing Application Instructions.

Lifespan and Maintenance

Have realistic expectations for roll roofing’s longevity and commit to basic maintenance.

- Expected Durability: A properly installed roll roof has a lifespan of 5 to 8 years. Factors like intense Texas heat and UV exposure can affect this.

- Regular Inspections: Inspect the roof twice a year (spring and fall) and after severe weather. Look for:

- Cracks, blisters, or loose seams.

- Exposed nail heads.

- Debris accumulation that traps moisture.

- How to Repair Small Holes or Tears: To fix minor damage, clean the area, apply roofing cement over the hole, press a small patch of roofing material into the cement, and seal the patch edges with more cement.

- Keeping the Roof Free of Debris: Regularly sweep off leaves and debris to prevent moisture buildup and decay.

By understanding these points, you can extend the life of your roll roofing. For general roofing repair guidance, our Guide to common roof repairs is a valuable resource.

Conclusion: Your Next Steps for a Perfect Roof

Mastering asphalt roll roofing installation is a valuable skill, offering an economical solution for low-slope structures in San Antonio, Helotes, and throughout Bexar County. This guide has covered the essentials, from material selection and preparation to step-by-step installation and maintenance. Following these steps—especially regarding temperature, precise measurements, and thorough sealing—is key to a durable, weather-resistant finish.

While roll roofing is a manageable DIY project, the integrity of your roof is paramount. For complex jobs or for the peace of mind that comes with professional craftsmanship and a warranty, consulting an expert is always wise. The certified team at Apex Roofing & General Contractors has extensive experience and adheres strictly to San Antonio building codes to ensure your roof is compliant and built to last.

If you’re in the San Antonio area—including Fair Oaks Ranch, Shavano Park, or Terrell Hills—and need a professional assessment or have questions about your roofing options, don’t hesitate to reach out. For a free estimate and to schedule your free inspection, call us today at (726) 727-7663 or explore our residential roof installation services. We’re here to help you achieve a secure and reliable roof.