Why a Small Hole in Your Metal Roof Demands Immediate Attention

A metal roof is a durable investment, often lasting 50 years or more. However, even the toughest roof can get punctured by hail, falling branches, or rust. Learning how to properly patch a hole in a metal roof is crucial to prevent costly water damage and extend its lifespan. For homeowners in Texas, where severe weather is common, having access to reliable roofing services in San Antonio provides essential peace of mind.

Quick Answer: How to Patch a Hole in a Metal Roof

- Clean the area: Remove all rust, debris, and dirt.

- Cut a metal patch: Ensure it’s at least 2 inches larger than the hole on all sides.

- Apply sealant: Use urethane roofing sealant around the hole.

- Secure the patch: Press it firmly and fasten with sheet metal screws.

- Seal completely: Apply sealant over the patch edges and screw heads.

- Test for leaks: After the sealant cures, spray the area with water.

This guide provides a complete walkthrough of the repair process, from safety and assessment to applying the final waterproof seal. Whether you’re a confident DIYer or want to understand the work before calling a professional, you’ll learn what it takes to achieve a perfect, long-lasting patch.

“A small puncture can quickly escalate into significant interior water damage,” says Carlos Yzaguirre, President of Apex Roofing & General Contractors. “Proper repair techniques can add decades to a roof’s life, protecting your home and your investment.”

First Things First: Safety, Tools, and Damage Assessment

Before you start, preparation is crucial. A successful metal roof repair begins on the ground with the right safety mindset, equipment, and a clear understanding of the damage.

Essential Safety Precautions for Working on a Metal Roof

Working on a metal roof is risky. They are extremely slippery when wet and can cause severe burns when hot.

- Work in Dry Conditions Only: Never work on a wet roof. Even morning dew can make metal panels treacherous. Plan your repair for a clear, calm day with temperatures above 50°F for optimal sealant performance.

- Use Proper Safety Gear: A safety harness is non-negotiable on steep pitches. Wear soft-soled roofing boots for grip, not sneakers.

- Secure Your Ladder: Place your ladder on level ground, extend it three feet above the eave, and have a partner hold it steady.

- Work with a Partner: A second person can hand you tools and call for help in an emergency.

For detailed federal guidelines, consult OSHA’s resource on Protecting Roofing Workers. If you are uncomfortable with heights, calling a professional is the smartest and safest decision.

Gathering Your Tools and Materials

Assemble everything you need before you climb the ladder to avoid accidents and save time.

- Safety Gear: Heavy-duty gloves, safety goggles, and a safety harness.

- Tools: Sturdy extension ladder, metal snips, wire brush, cordless drill, and a caulking gun.

- Materials: A metal patch matching your roof, high-quality urethane roofing sealant, pan-head sheet metal screws with rubber washers, an all-purpose cleaner, and clean rags.

Using the correct materials is vital. The patch should match your existing roof to prevent galvanic corrosion, and the sealant must be rated for metal roofing to handle temperature-related expansion and contraction.

Identifying the Cause and Extent of the Damage

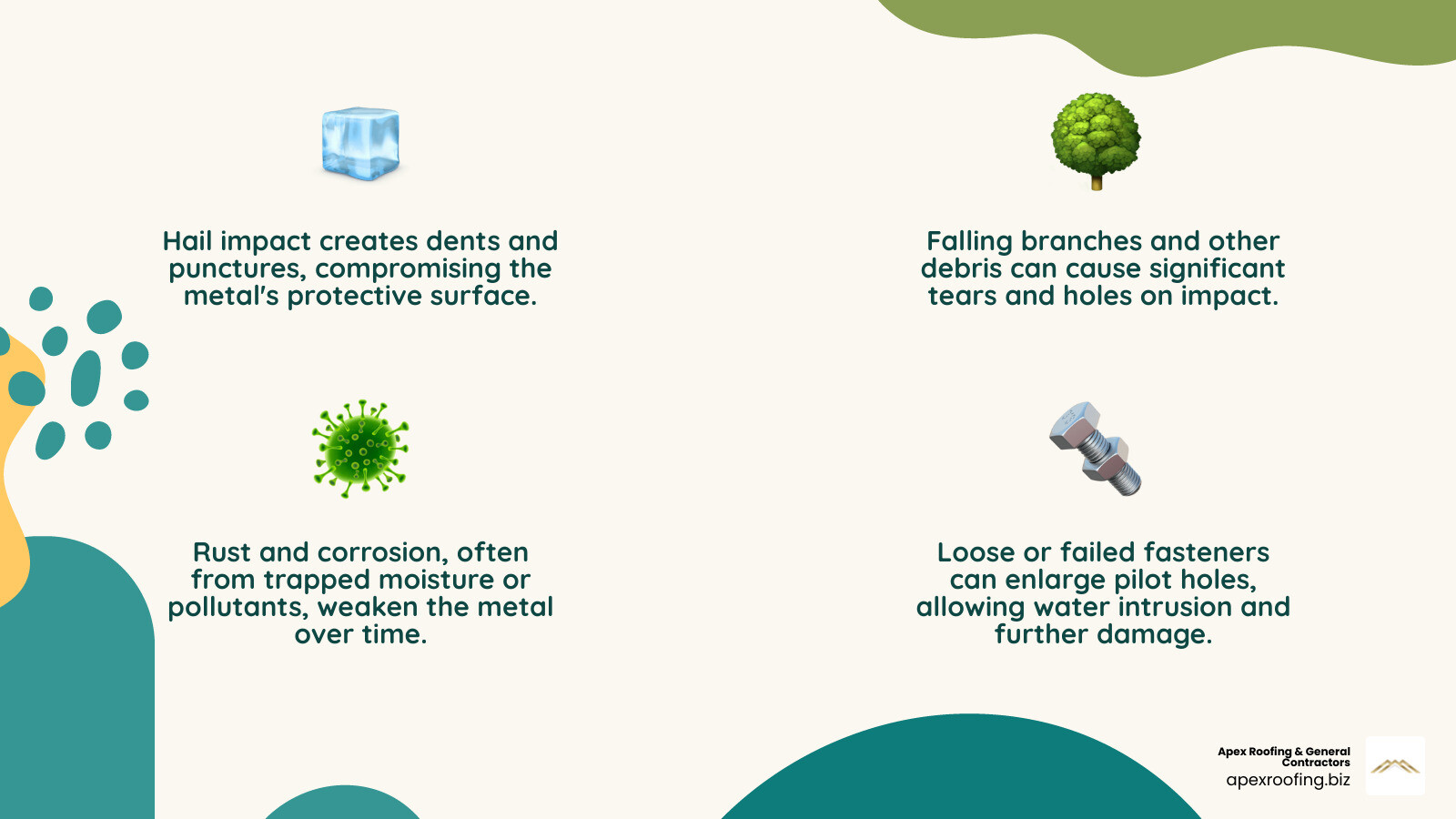

Understanding why the hole exists helps prevent future problems.

- Physical Damage: Punctures from fallen branches or dropped tools are usually straightforward to repair.

- Hail Damage: Common in Texas, large hailstones can puncture metal panels. Our guide on What Hail Size Causes Roof Damage? offers more context.

- Rust and Corrosion: This occurs when protective coatings wear off, exposing the metal to moisture.

- Loose or Failed Fasteners: Over time, screws can work themselves loose due to thermal expansion, creating entry points for water.

- Galvanic Corrosion: This electrochemical reaction happens when incompatible metals (e.g., a steel screw on an aluminum panel) touch in the presence of moisture.

Assess the overall damage. A single small hole is a manageable DIY project. However, multiple holes, widespread rust, or buckling panels require professional expertise to avoid making the problem worse.

The Step-by-Step Guide to Patch a Hole in a Metal Roof

With your prep work done, you’re ready to perform the repair. A properly installed patch can last over a decade, providing long-term protection. Follow these steps carefully to patch a hole in a metal roof and create a durable, watertight seal.

Step 1: Prepare the Roof Surface for Repair

A clean surface is the most critical factor for a lasting patch. Any repair will fail if this step is rushed.

First, thoroughly clean a 6-inch radius around the hole with an all-purpose cleaner and rags. Next, use a wire brush to scrape away all visible rust until you reach bare, clean metal. Scuff the clean surface lightly with sandpaper or the wire brush to create a texture for the sealant to grip. Finally, wipe the area one last time to remove any dust or oils and allow it to dry completely.

Step 2: Cut and Shape Your Metal Patch

Your patch is the new barrier, so size and material are key.

- Measure and Cut: The patch must be at least 2 inches larger than the hole on all sides. A 2×2 inch hole requires a minimum 6×6 inch patch. Use metal snips for clean cuts.

- Round the Corners: Use the snips to slightly round the corners of your patch. This prevents them from catching debris and lifting over time.

- Match the Metal: Ensure your patch material is the same type as your roof to prevent galvanic corrosion.

Step 3: Apply the Patch and Sealant

This step creates the waterproof seal. Be generous with your sealant.

Apply a thick, continuous bead of urethane roofing sealant around the hole’s perimeter. Press the patch firmly into the sealant, ensuring it is centered. You should see sealant ooze out from the edges. Secure the patch with pan-head sheet metal screws every 2-3 inches around the perimeter, about 1 inch from the edge. Do not overtighten. Apply a second layer of sealant over the patch’s edges and each screw head. Use a putty knife to smooth the sealant for a clean, feathered finish.

Step 4: Test and Finish Your Repair

A final check verifies that your repair is secure.

Allow the sealant to cure fully according to the manufacturer’s instructions, which typically takes 24-48 hours. Once cured, perform a water test by spraying the patch with a garden hose for several minutes. Check inside your attic or on the ceiling below for any signs of moisture. If the area is dry, your repair is successful. For aesthetic purposes, you can paint the patch with a compatible paint to match your roof color.

For complex issues or if you prefer professional assistance, our expert team provides comprehensive roof repair services throughout the San Antonio area.

Professional Repair vs. DIY: When to Call the Experts

While patching a small puncture is a manageable DIY project, many situations require professional expertise to prevent costly mistakes. The average cost for a professional patch is around $375, an investment that buys expertise, a warranty, and peace of mind.

Assessing When a DIY patch hole in a metal roof is not enough

Knowing your limits is key. A simple patch is insufficient in the following situations:

- Multiple Holes: Scattered holes often signal a systemic issue like widespread corrosion or severe hail damage.

- Large Damaged Area: If damage covers more than 30% of a single roof section, replacement is often more cost-effective than repair.

- Widespread Rust: Extensive corrosion indicates a failure of the roof’s protective coating and requires more than a patch.

- Buckling or Wrinkling Panels: These are signs of structural stress or improper installation that demand professional diagnosis.

- An Aging Roof: A roof over 20 years old with multiple issues may be near the end of its life. A professional can help you decide between continuous repairs and a full Roof Replacement in San Antonio.

- Safety Concerns: If you are uncomfortable with heights or working in unfavorable conditions, always call a professional.

The Cost of Patching a Metal Roof

This table breaks down the expected costs for both approaches:

| Factor | DIY Repair | Professional Repair |

|---|---|---|

| Average Cost | $15 – $50 (materials only) | $150 – $600 (average for a single hole) |

| Materials | Standard sealant, generic patch | Commercial-grade, custom-matched materials |

| Labor | Your time and effort | $50 – $80 per hour for skilled contractors |

| Warranty | None; may void existing roof warranty | Workmanship guarantee on the repair |

| Best For | Single, small, easily accessible punctures | Large holes, multiple leaks, structural issues, warranty preservation |

Why Choose a Professional for Your San Antonio Roof Repair?

For homeowners in San Antonio and surrounding areas like Helotes and Shavano Park, choosing a local professional like Apex Roofing & General Contractors offers significant advantages.

Safety and liability are handled by our trained and insured team. We have access to correctly matched materials to prevent corrosion and ensure aesthetic consistency. Our team’s knowledge of local building codes ensures your repair is compliant and passes inspection. We use professional-grade equipment and high-performance sealants designed for Texas weather, and every repair includes a workmanship guarantee. Crucially, a professional repair can preserve your existing roof warranty, which a DIY fix will likely void.

For expert assistance with any metal roof issue, call us at (726) 727-7663 for a free inspection.

Frequently Asked Questions about Metal Roof Repair

Here are answers to the most common questions San Antonio homeowners have about fixing metal roofs.

What’s the difference in repairing holes on flat panels versus raised seams?

Repairing a hole on a flat panel is straightforward: you apply a rigid patch directly to the surface. Raised seams (or standing seams) are designed to allow metal panels to expand and contract with temperature changes. A repair on or near a seam must accommodate this movement. Instead of a rigid patch, professionals use flexible materials like asphalt-impregnated fabric or specialized sealants that can stretch with the metal, preventing the repair from cracking.

What causes metal roof holes besides obvious physical damage?

Beyond impacts from hail or branches, holes often develop from slower, less obvious causes:

- Corrosion: Airborne chemical pollutants or coastal salt spray can break down the roof’s protective coating, leading to rust and eventually holes.

- Galvanic Corrosion: This occurs when two different types of metal (like a steel screw on an aluminum panel) touch in the presence of moisture, causing one metal to corrode rapidly.

- Prolonged Moisture: Poor drainage or debris can trap water on the roof, accelerating rust, especially around seams and fasteners.

- Freeze-Thaw Cycles: Water that seeps into tiny cracks can freeze, expand, and widen the opening over time.

- Loose Fasteners: Thermal expansion can cause screws to loosen, enlarging the screw hole and creating a leak point.

Will a DIY patch hole in metal roof affect my warranty?

Yes, a DIY repair will almost certainly void your roof’s warranty. Manufacturers and installers require that any repairs be performed by an authorized contractor to ensure proper techniques and materials are used. An improper repair can cause further damage, and manufacturers will not cover issues resulting from unauthorized work. Before attempting a DIY fix, always read your warranty documents and consider calling a certified professional to protect your investment.

Should an entire metal roof be replaced if there are multiple holes?

Not always. The decision depends on the overall condition of the roof.

- Repair is a good option when the holes are isolated, the damage covers less than 30% of the roof, and the roof is under 20 years old and otherwise in good shape.

- Replacement is the better choice when you have widespread holes, extensive rust, or structural issues like buckling panels. If a roof is over 20 years old and showing multiple signs of failure, replacement is a more durable and cost-effective long-term solution than continuous patching.

A professional inspection is the best way to get an honest assessment. If you’re unsure about your roof’s condition, call us at (726) 727-7663 for a free inspection.

Conclusion

Learning to patch a hole in a metal roof is a valuable skill that protects your home from water damage and extends the life of your roof. A careful repair using quality materials can last for years. However, it is crucial to recognize when a problem is too big for a DIY fix. Widespread rust, multiple holes, or structural issues demand professional expertise to avoid making a small problem much worse.

At Apex Roofing & General Contractors, we have years of experience helping San Antonio homeowners with these exact situations. We understand local building codes and how Texas weather affects metal roofs, and we stand behind our work with solid warranties.

Whether you tackle the repair yourself or call in the pros, the most important step is to address the hole quickly before water causes more damage.

Ready to ensure your metal roof is perfectly sealed and protected? Our team is here to help with everything from minor repairs to complete replacements. Explore our expert metal roofing services for a free estimate, or call us at (726) 727-7663 for a free inspection. We will provide an honest assessment and recommend the best path forward to protect your home for decades to come.