Why EPDM Flat Roof Repair Matters for Your Property

EPDM flat roof repair is a crucial skill for property owners with synthetic rubber roofing systems. EPDM (Ethylene Propylene Diene Monomer) roofing has proven its worth for over 50 years, covering millions of square feet on commercial and residential buildings. Its flexibility and durability make it ideal for flat roofs, but like any material, it can develop leaks over time from punctures, seam separation, or membrane shrinkage.

The good news is that many EPDM repairs are straightforward DIY projects when caught early. For property owners in San Antonio seeking reliable commercial roofing solutions, understanding basic repair techniques can prevent small issues from becoming expensive disasters.

I’m Carlos Yzaguirre, President of Apex Roofing & General Contractors. I’ve spent years helping San Antonio property owners maintain their roofing investments. Through countless EPDM flat roof repair projects, I’ve learned that proper technique and quality materials make all the difference in creating lasting repairs.

Identifying Common EPDM Roof Problems

When it comes to EPDM flat roof repair, knowing what to look for can save you thousands. EPDM roofing is a reliable synthetic rubber membrane known for its flexibility and resistance to UV radiation and extreme weather. However, even the best materials aren’t immune to problems, and catching them early is key to preventing a small leak from turning into a major disaster.

The most common issues are seam failure, where adhesives break down, and punctures or tears from debris or foot traffic. Over time, membrane shrinkage can pull at edges and create tension, while ponding water—water that sits for over 48 hours—can accelerate deterioration and stress seams.

Signs You Need a Repair

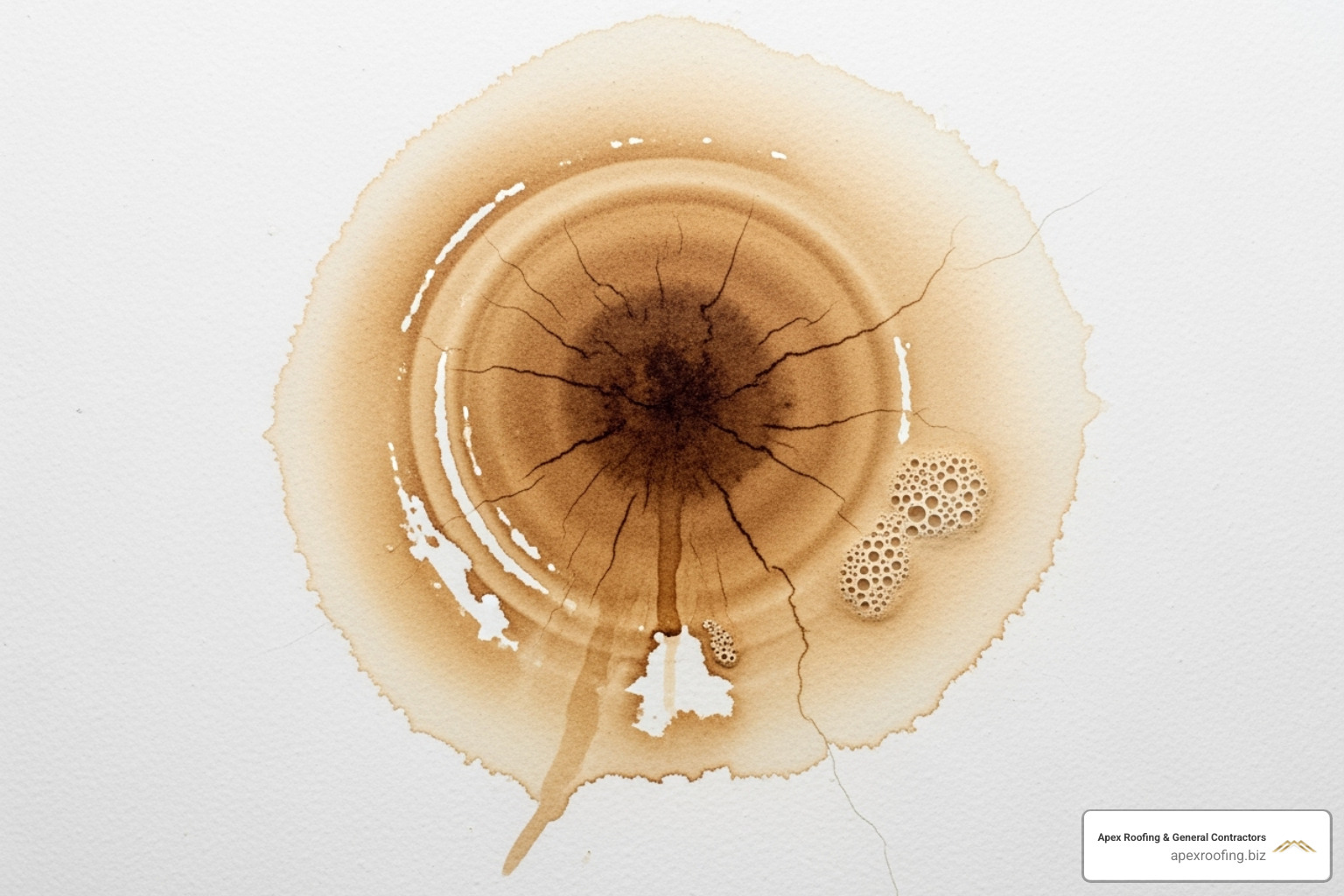

Your roof will give you warning signs before a small problem escalates. The most obvious red flag is water stains on your ceiling. Inside your attic, check for damp or discolored insulation. On the roof itself, look for visible tears, cracks, or punctures. Pay close attention to cracked or separated seams, as these are common leak points. Other signs include bubbling or blistering of the membrane, loose flashing around edges and penetrations, and debris accumulation that traps moisture.

Locating the Source of the Leak

Finding a leak can be tricky, as water often travels from the entry point before showing up as a ceiling stain. Start your investigation inside by noting the location of any drips or stains. Then, head to the roof and inspect the area directly above the interior damage, expanding your search outward and uphill.

Look for obvious punctures, loose seams, or ponding water. If the source isn’t apparent, you can perform a controlled water test with a garden hose, wetting small sections at a time while a partner checks for leaks inside. Once you find the culprit, mark the area clearly so your EPDM flat roof repair targets the right spot.

For more detailed guidance, check out this resource on inspecting EPDM roofs. If you’re dealing with extensive damage or multiple leaks, it may be time to call for professional help. We offer emergency commercial roof repair services when you need help fast. For a thorough assessment, call us at (726) 727-7663 to schedule a free estimate and inspection.

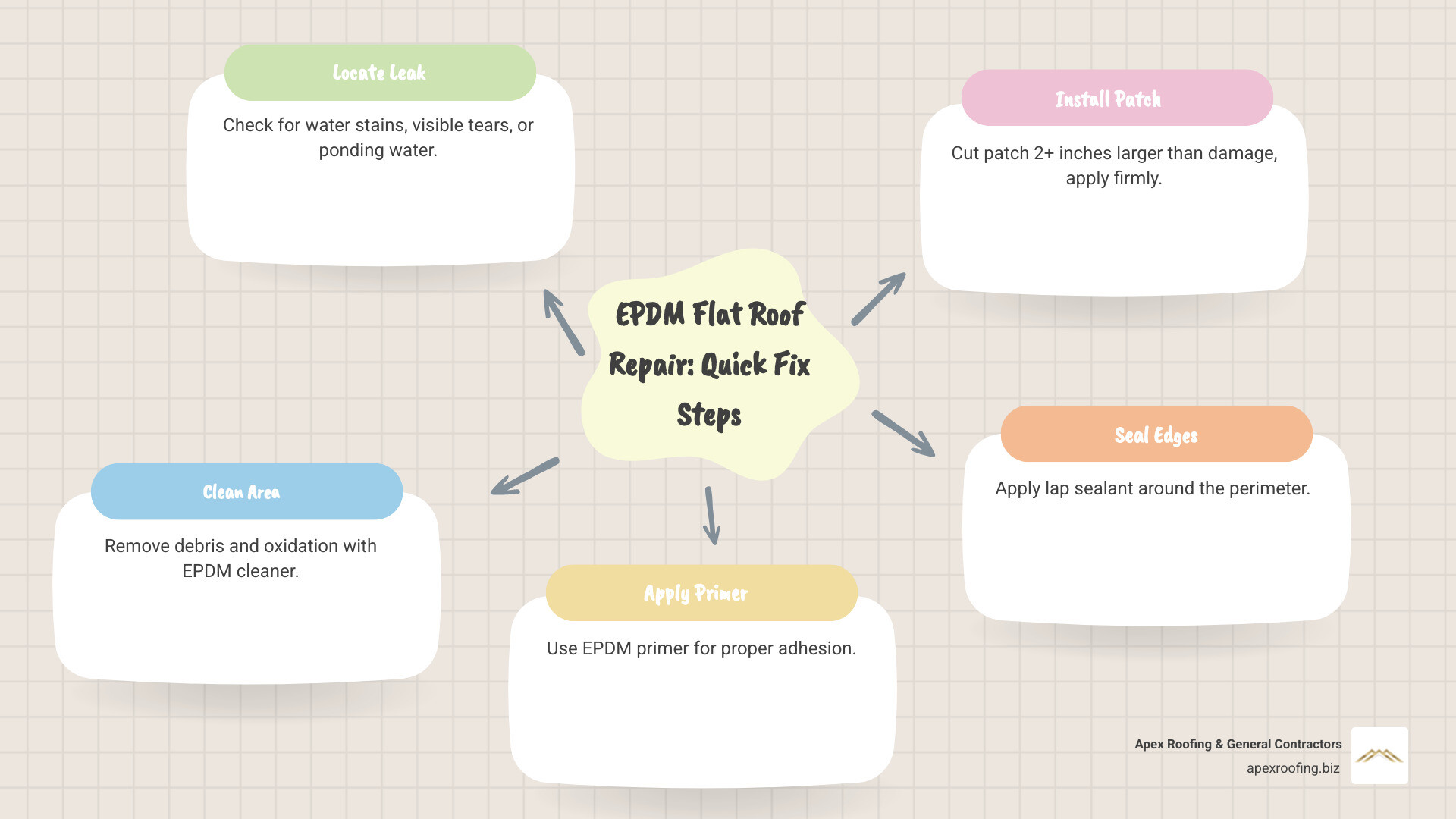

Your Step-by-Step Guide to EPDM Flat Roof Repair

Ready to tackle your EPDM flat roof repair? With the right approach, many minor issues can be fixed without calling in the pros. Before you begin, prioritize safety: always have a spotter on the ground and avoid working in wet or windy conditions.

Preparing for Your EPDM Flat Roof Repair

A lasting EPDM flat roof repair depends on proper preparation. Just as you wouldn’t paint a dirty surface, you can’t patch a dirty roof.

Gathering Your Arsenal

For tools, you’ll need a utility knife, a stiff brush, a paint roller, a steel seam roller, and a caulk gun. For materials, get an EPDM patch kit, EPDM-specific cleaner, clean rags, and lap sealant.

Weather: Your Make-or-Break Factor

EPDM adhesives and primers require temperatures above 45-55°F to cure correctly. Crucially, the roof surface must be completely dry. If rain is in the forecast within 24-48 hours, postpone the repair. Waiting for the right conditions is better than redoing the job.

The 5-Step Patching Process

Once you have your materials and good weather, you’re ready to begin.

Step 1: Surface Preparation

Clear away debris with a stiff brush. Then, deep clean the damaged area and at least 6 inches around it with EPDM cleaner to remove dirt and oxidation. Rinse and let it dry completely. If the underlying insulation is wet, you must cut out the damaged section and replace it before patching.

Step 2: Cutting Your Patch

Cut a patch that extends at least 2 inches beyond the damage on all sides. A pro tip is to round the corners of the patch, as square corners are more prone to peeling over time.

Step 3: Priming the Surface

Apply a thin, even layer of EPDM primer to the cleaned area. Let it flash off according to the manufacturer’s instructions, which usually takes a few minutes.

Step 4: Applying the Patch

For a pressure-sensitive patch, peel off the backing and place it carefully. Once it’s down, it’s committed. Immediately use a steel seam roller, working from the center outward to eliminate air bubbles and ensure a firm bond.

Step 5: Sealing the Deal

Apply a continuous bead of lap sealant around the entire perimeter of the patch, covering the edge where it meets the existing membrane. Smooth the bead for a seamless finish. Allow the repair to cure fully before walking on it.

If you’re facing extensive damage, it might be time for an expert. At Apex Roofing & General Contractors, we offer free estimates. Call us at (726) 727-7663 to schedule your free inspection.

Maintenance and Prevention for a Longer Lifespan

A successful EPDM flat roof repair is great, but preventing problems is even better. Just like regular oil changes for a car, routine roof maintenance costs far less than major repairs. After years of working with all types of commercial flat roofs in San Antonio, I can confirm that property owners who prioritize maintenance rarely face roofing emergencies.

Best Practices for EPDM Roof Care

Semi-annual inspections in the spring and fall are your roof’s best friend. After severe weather, do a quick check for loose seams, punctures, or debris. Keep the roof clean by removing leaves and branches, and ensure drains and scuppers are clear to prevent ponding water. Trim overhanging branches to avoid scrapes and punctures. It’s also wise to limit foot traffic; if regular access is needed, install protective walk pads. Be mindful of chemical contamination from HVAC units or vents, as grease and oils can damage EPDM. If you see water ponding for more than 48 hours, address the drainage issue immediately.

Patches vs. Coatings: Which Repair is Right?

For an EPDM flat roof repair, you have two main options: patches or liquid coatings. Think of patches as band-aids for specific issues and coatings as a protective shield for the whole roof.

EPDM patches are ideal for localized damage like punctures, tears, or small seam separations. They are a quick and effective fix for isolated problems.

Liquid EPDM coatings are better for widespread surface wear, aging roofs with many small cracks, or reinforcing all seams. A coating provides a seamless, uniform layer that can extend your roof’s life by 5 to 15 years. Light-colored coatings also improve reflectivity, creating a “cool roof” that can lower energy costs. While patches are great for DIY repairs, applying a full coating is often a job best left to professionals to ensure proper adhesion and coverage.

For a single hole, use a patch. For an aging roof with widespread issues, a liquid coating is likely the better long-term investment.

When to Call a Professional Roofer

While many EPDM flat roof repair tasks are DIY-friendly, it’s crucial to know when to call for professional expertise. Pushing beyond your skill level can turn a simple fix into a costly disaster. Minor punctures are manageable, but extensive damage, multiple leaks, or structural problems require a pro.

Signs Your Roof Needs More Than a DIY Fix

Here are red flags that indicate you need professional help:

- Large tears exceeding 12 inches often signal underlying issues a patch can’t fix.

- Widespread seam separation points to a systemic failure of the original installation or aging adhesives.

- Significant ponding water that remains for over 48 hours suggests structural or drainage problems.

- Soft or spongy spots underfoot mean the insulation or decking is saturated and must be replaced.

- Membrane shrinkage that pulls away from walls or penetrations puts the entire system under stress.

- An aging roof (15-20+ years) with persistent leaks may be at the end of its service life, making continued repairs a poor investment.

- Safety concerns, such as a fear of heights or lack of proper equipment, are always a reason to call a professional.

Ignoring these signs can lead to devastating consequences. Water intrusion can cause wood rot, metal corrosion, mold growth, and compromised structural integrity, ultimately diminishing your property’s value and safety.

Advanced EPDM Flat Roof Repair: Beyond Simple Patches

Professional repairs go far beyond simple patches. Tasks like membrane or insulation replacement, correcting roof pitch for proper drainage, and making structural repairs to decking require specialized knowledge and equipment. A professional assessment is crucial to determine if repairs are cost-effective or if a roof replacement is the better option.

For complex issues, a certified contractor in the San Antonio area like Apex Roofing & General Contractors can provide a professional assessment and ensure all work complies with local codes. We have experience with every type of EPDM flat roof repair challenge across San Antonio, Helotes, Leon Valley, Alamo Heights, and the surrounding Bexar County communities.

When facing extensive damage or safety concerns, don’t hesitate to call for help. We offer free estimates and thorough inspections to help you make an informed decision. Call (726) 727-7663 to schedule your free inspection.

Frequently Asked Questions about EPDM Roof Repair

Property owners often have questions about EPDM flat roof repair. Here are answers to some of the most common ones I hear from building owners in San Antonio.

How long does an EPDM roof patch last?

A properly installed patch using the correct materials can last for many years, often for the remaining life of the roof. The key is meticulous surface preparation: thoroughly cleaning the area, using the right primer, and rolling the patch firmly to create a durable, watertight bond. However, if the underlying membrane is old or severely deteriorated, a patch may only be a temporary solution.

Can I repair an EPDM roof in any weather?

No. This is a critical factor for a successful repair. EPDM adhesives and primers require specific conditions to cure properly. The ideal time for a repair is on a dry day with temperatures above 45-55°F (7-13°C) and no rain in the forecast for at least 24 hours. Attempting a repair in cold or wet conditions will likely lead to failure.

How does EPDM repair compare to TPO or PVC?

EPDM is a thermoset material, meaning it’s cured during manufacturing and can’t be re-melted. Therefore, EPDM flat roof repair uses adhesives, primers, and sealants in a “cold” application process. In contrast, TPO and PVC are thermoplastics, which can be softened with heat. Their seams and patches are typically heat-welded with specialized equipment. This makes EPDM patching more accessible for DIY repairs, as it doesn’t require a hot-air welder.

Conclusion

A small leak can quickly escalate into thousands of dollars in structural damage. Fortunately, with the right knowledge, you can confidently handle minor EPDM flat roof repair projects to protect your property. The key to a lasting repair is proper surface preparation, using the right materials, and taking your time. Rushing the job often leads to failed patches.

However, it’s just as important to recognize when a problem is too big for a DIY fix. If you’re facing extensive damage, multiple leaks, or if your roof is nearing the end of its lifespan, it’s time to call in a professional. Some jobs simply require an expert’s tools and experience.

At Apex Roofing & General Contractors, we’ve seen what happens when small problems are ignored. Our certified team provides transparent communication and ensures every repair meets local building codes, giving you peace of mind. Don’t let a minor leak become a major headache.

Call us at (726) 727-7663 to schedule your free estimate and inspection. Get expert advice on your commercial roofing needs and protect your investment. Your roof will thank you.